To keep a continuous flow of good product moving through your process, irregularities must be identified quickly, the process stopped, and corrections made. We will explore the specifics of jidoka, its benefits, and how it can be used in your organization to quickly stop and eliminate problems that might result in defective products.

Overview: What is Jidoka?

Sakichi Toyoda, the founder of the Toyota Group, conceived the concept of jidoka in the early 1900s. His inspiration came from his invention of a unique textile loom that automatically stopped when one of the threads broke.

Previously, the loom would churn out mounds of defective fabric if a thread broke, and no one noticed. As a result, each machine had to be watched by an operator. Jidoka allowed one operator to control multiple machines since the machine experiencing the broken thread would shut down on its own.

A common synonym for jidoka is autonomation, which combines the concepts of autonomous and automation.

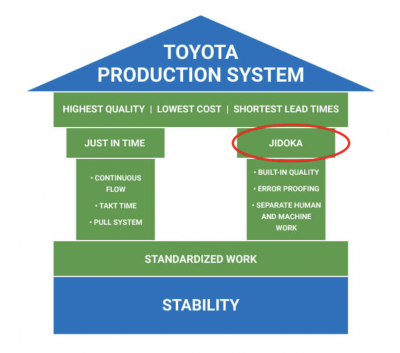

Jidoka is one of the two foundations of the Toyota Production System (TPS), the other being Just In Time (JIT). The graphic below shows the elements of TPS.

Here is a look at the evolution of jidoka.

Jidoka is based on four principles:

- Discover the abnormality or irregularity

- Stop the process

- Fix the immediate problem

- Install countermeasures to prevent the problem from occurring again

Under what conditions would you want the process to be stopped?

- Quality issues

- If a defective part continues to be processed, cost and effort are added and will be wasted if the part is subsequently scrapped.

- The more work added, the more effort it will take to fix the issue if the product is salvaged later on.

- Any delay between the cause of the problem and its detection may lead to more defective products later on.

- In the case of a rare problem occurrence, a delay between the cause and the detection may mean the problem is no longer active. This can make it more difficult to determine the root cause of the problem and find a solution.

- Process issues

- There may be process issues that may not lead to an immediate quality issue, but the process should still be stopped.

- For example, if a machine is overheating, it should be stopped and investigated. Even if the quality of the parts is still good, an overheating machine may eventually lead to defective parts, or to a machine breakdown or injury to the operator.

- Material supply issues

Therefore, it is very important for jidoka to have an automatic stop for any kind of abnormality; quality, process, or material. If the machine continues with abnormalities, the costs down the line would multiply. Additional tools to use with jidoka can include poka yoke and andon lights.

Stopping the process is the key to jidoka. However, after the process has stopped, there should be a focus on starting up again once the immediate issue has been resolved. Depending on the reason for stopping, you will want to invest time and effort to not only apply a quick fix, but put countermeasures in place to eliminate the root cause of the stop and prevent it from happening again.

3 benefits of jidoka

Jidoka is intended to automatically prevent a machine from producing defective products. By doing that, you will accrue the following benefits.

1. Prevents wasted time

Jidoka is designed to automatically stop a machine if an abnormality is detected. This prevents additional defectives from being produced.

2. Operator can operate multiple machines

By having a machine automatically shut down if an anomaly is discovered, the operator does not have to constantly watch a machine. They can operate multiple machines at one time, making the process more productive.

3. Early detection of abnormalities

Instead of a long machine run continuing to produce bad products, a problem can be found and quickly corrected.

Why is jidoka important to understand?

Jidoka is a foundational element of the Toyota Production System and can serve as a powerful tool for implementing lean manufacturing in your organization.

Key to better quality products

Since machines are designed to quickly shut down if bad products are being produced, you will produce more good products to meet your customer demand. You will also be more confident you are shipping defect free products.

Improves work environment

It can be boring for an operator to stand and watch a machine. By allowing them to be more productive and active, they will enjoy their work more and be more satisfied with their work environment.

Reduces costs

Your costs will be reduced by eliminating excessive defective products and having operators be more productive.

An industry example of jidoka

A simple example of how jidoka works can be found in a printer. Your printer is designed to stop automatically if the toner (or ink) is low. If the printer didn’t stop automatically, you would waste paper or print a large document where the first pages are good, but subsequent pages would decrease in quality.

Another example of an automatic stop in a printer is paper jams. If the printer detects a page is jammed somewhere in the printer, it will: Stop the print, alert you to the jam, provide an indication of where the jam occurred, and provide instructions on how to fix it. After the jam is cleared, the printing will continue.

If the printer did not stop automatically, you could waste time, toner, and paper — and probably damage your printer. Additionally, you don’t have to stand around while your document is being printed; you’ll know that if something goes wrong, the printer will automatically shut down.

3 best practices when thinking about jidoka

Jidoka is often referred to as the forgotten pillar of the Toyota Production System, with the primary attention paid to Just In Time. These tips will let you bring the appropriate importance to this important tool.

1. Stop means stop

Once a machine has automatically stopped, don’t start it up again until the current problem is resolved.

2. Fix the current problem, but also prevent it from happening again

You must fix the initial problem to get the machine running again, but don’t forget to analyze the root cause of the problem and implement longer-term countermeasures to prevent it from happening again.

3. Combine jidoka with chaku chaku

The automatic ejection of parts using a chaku chaku system combined with the auto stop concept of jidoka will provide a system for optimizing your process and operator productivity.

Frequently Asked Questions (FAQ) about jidoka

When was jidoka first used in business?

In 1896, Sakichi Toyoda, the founder of the Toyota Motor Company, invented a textile loom that would automatically shut down if one of the threads broke.

What are the principles of jidoka?

Jidoka is based on four principles:

- Discover the abnormality or irregularity

- Stop the process

- Fix the immediate problem

- Install countermeasures to prevent the problem from occurring again

Is jidoka a part of the Toyota Production System?

Yes, it is one of the two major pillars of TPS. The other pillar is Just In Time.

Jidoka recap

Jidoka is a concept and approach where machines are designed to automatically stop if an abnormality is detected. This prevents the process from producing additional bad products and passing them down the line. It also allows for operators to run multiple machines since they don’t have to monitor a machine closely and manually intervene.