Process capability is the comparison of the output of your in-control process with the customer’s expectations, specifications or requirements. Let’s learn a little more about how to calculate your process capability.

Overview: What is process capability?

Process capability is the quantifiable comparison of the Voice of the Customer (specs, requirements, or expectations of your customer) and the Voice of the Process (control limits). The goal of process capability is to come up with a quantifiable measure of how well you are meeting your customer expectations. The comparison is made by using the ratio of the difference between the process specifications to the variation of the process values, as measured by 6 process standard deviations.

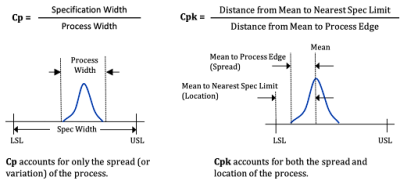

There are a number of different metrics for measuring process capability. One of the most common is Cpk or Capability Index. Other calculated metrics include; Cp, Pp and Ppk. The graphic below illustrates the concept of process capability and the formulas for the two most common capability metrics.

An industry example of process capability

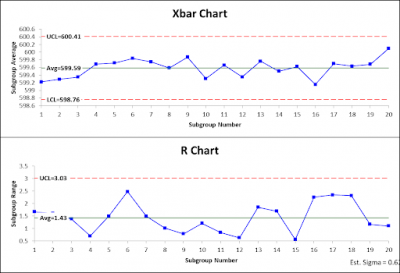

As a result of increased complaints about quality, Jack, the company Black Belt (BB), was reviewing the control charts and process capability of his two main suppliers of corrugated containers. Below are the control charts monitored by the quality department. As you can see, Supplier 1 shows their process is in-control.

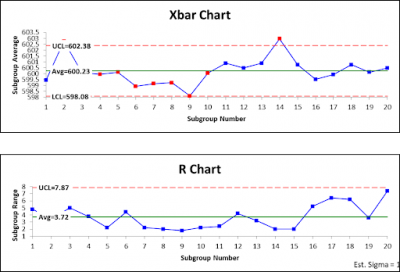

Since Supplier 2 is not in-control, process capability can’t be computed. A decision was made to stop ordering from Supplier 2 until the company is able to figure out how to stabilize their process. Supplier 1’s process was in-control and capable so they got the additional business and quality complaints disappeared.

Frequently Asked Questions (FAQ) about process capability

Must my process be in-control before doing process capability?

Yes. Process capability is a forward looking projection of how well you will be able to meet your customer’s requirements. Unless a process is in-control and just showing common cause variation, the future is hard to predict and your process capability assumptions may not be accurate.

Does process capability assume normality of the data?

Most capability calculations have an underlying assumption of normality of your data. If your data is not normal, you can either transform the data (Box-Cox or Johnson) or use special capability calculations based on the specific distribution of your data.

What is the difference between Cp and Cpk capability calculations?

Cp is calculated on the assumption that the mean of your data is centered within your upper and lower specifications. Cpk allows for the non-centering of your data and is calculated based on the specification closest to your data mean.