Your company has just announced that its product line has a 100% total throughput rate, touting it as a great win for everyone. However, from your perspective, you see massive amounts of rework being performed, disrupting the production lines, costing additional money, and impacting on-time delivery. If only there was an easy-to-see metric that could help show the company that while total throughput rates are high, the production line has serious problems that need to be addressed.

That metric does exist, and it is called rolled throughput yield.

An overview: What is rolled throughput yield?

Rolled throughput yield is the probability of a product or service making it through the entire process without having a single defect. Ideally, you want this value to be 100%, but that can only happen if all products pass each process step 100% of the time.

This is a valuable tool for opening the eyes of people regarding how defects are impacting a process. Many processes, especially when dealing with expensive product, will simply rework a product that exhibits failures until it passes, arriving at a total throughput yield of near or at 100%.

On the other hand, rolled throughput yield does not factor in rework, screening out any product that has a single failure along the way. When a process has a high total throughput yield and a low rolled throughput yield, it’s a sign that large amounts of rework are being performed. This rework is waste that adds cost and negatively affects delivery rates.

Calculating rolled throughput yield with an example

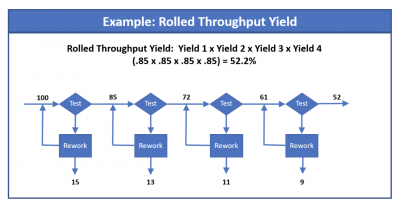

The formula for rolled throughput yield is to multiple the passing rate of all the steps within the process together.

Rolled Throughput Yield = Yield 1 x Yield 2 x …. Yield N (N representing the yield of the final process step)

For our example, let’s say we have four processes, and at each process there is a 15% first pass failure rate. So, for every 100 products passed, 85 pass and 15 fail.

Using the formula, you multiple the pass percentage of each of the stages together. Whether the products that failed are reworked or scrapped is not relevant for rolled throughput yield, as rolled throughput yield is only concerned with the items that pass the first time, every time.

So, 85% multiplied by itself four times (the number of processes, each with an 85% pass rate) will gain you an answer of 52.2%. On average, 52 products out of 100 will arrive at the end of the process without having a single failure along the way.

What this helps demonstrate is even with a relatively high level of success at each step, once you factor them all together, a much smaller group makes it through the entire process without experiencing a single failure.

3 best practices for rolled throughput yield

If your process improvement resources are limited, focus on the one or two steps with the lowest first pass yield. These steps typically present you with the largest opportunity to improve rolled throughput yield.

Once you have acquired the rolled throughput rate, work on giving a dollar amount to the lost value through wasted components and rework. Managers are likely to give more attention to the lost value figures than to the more abstract concept of rolled throughput rate.

Failure rates are affected not just by problems with the process, but by the inputs to the processes. Be sure to address any issues with parts (or information) that are causing problems with yields.

Frequently Asked Questions (FAQ) about rolled throughput yield

My processes are working at a nice 95% first pass yield rate, but my rolled throughput rate is just under 60%. Is the process still performing poorly?

This is a great example that shows even when first pass yield rates seem high, there is still improvement efforts to be made to the process. The rolled throughput rate is a factor of the first pass yield rates of each step being multiplied together.

With this case, 10 steps all with 95% first pass yields rates will be about 60%, which is not as high as you would like. This shows how even 5% of products, when accumulated over many steps, can add up to be a large quantity of rework. Keep working on getting the first pass yields at different steps higher, and your rolled throughput yield will begin to climb higher.

My rolled throughput yield is 100%. Does that mean I have eliminated all waste from the system?

No, it does not, though it is good news. A 100% rolled throughput yield means that you have eliminated all rework from the system, but the state of other wastes are not represented with this metric. You may still have large travel distances, larger than needed inventories, and completely unnecessary steps within the process.

How often do I need to calculate rolled throughput yield?

Many companies do a poor job, or don’t even calculate rolled throughput yield. If you have a quality data management system that collects yield information, you can regularly check the value over given timeframes. In manual situations it can be more difficult to collect, but it can be calculated.

In these manual situations, it is recommended to check your yield information at least once a month. While more often is desired, it can be cost prohibited when needing to collect the information manually on a regular basis. This is why quality management systems are so critical in today’s work environments.

Office environments are perhaps the worst situations, as so few of them have the capability to collect the information, or even properly designate what qualifies as a pass and what qualifies as a failure. Usually, if the work has to be sent back to a previous step, it is considered a failure, and determining how that data is collected regularly is a challenge.

Rolled throughput yield is a great metric to give you a quick glimpse into the impact of rework

Rolled throughput yield is a great way to show how rework is affecting your production line or office processes. When used in conjunction with other yield values, it can help give a more complete picture as to how poor quality affects the day-to-day operation. Remember that any time spent doing a task more than once is waste.