During the most recent review of the process control charts, someone noticed that the process fell out of control. Thankfully, it was noted that not a single piece of equipment failed specification checks. One of the operators asks you, “Why do we have two measurements to monitor, control limits and specification limits?” Randomly pointing at one of the values on the chart, she asks, “What even is an upper specification limit?”

An overview: What is an upper specification limit?

The upper specification limit, or USL, represents the highest limit a measurement or reading can reach and still be acceptable to the customer.

To understand why we need specification limits, it helps to understand control limits. A control limit represents the expectations of a process for a sample to be outside a given percentage range expectation. If we use a 95% range expectation, or +/- two standard deviations, it can help demonstrate the expectation of a reading being within a range with 95% certainty.

Specification limits are different from control limits, as they are not calculated using means and standard deviations but are instead values determined by the designers (via the customer) to be within acceptable quality boundaries. They are what is acceptable to the customer. If the specifications, either upper or lower, are inside of the of the control limits boundaries, then the process is considered not capable, as the process could be operating within acceptable variation parameters and still deliver a product that is not within specification.

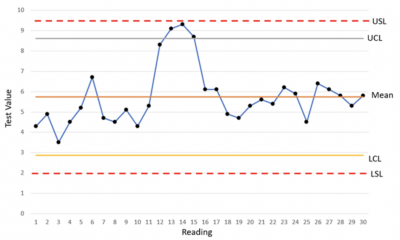

Let’s look at the example below. The X-bar R chart shows the data over a period of time, the mean, specification limits, and control limits (set at 95%, or +/- 2-sigma). It shows when the process went out of control — during readings 12-15. When the process was out of control, it ran the risk of being out of specification, though in this example, it did not pass the upper or lower specification limit ranges, meaning the process was in acceptable parameters for the customer.

3 benefits of attending to upper specification limits

Seeing where it compares with the upper control limit

If the upper control limit is higher than the upper specification limit, then the process can be considered capable, assuming that the inverse is said regarding the lower control and upper specification limits. If not, the process is considered not capable of reliably providing a product that will meet customer requirements.

Easy spotlight for process improvement opportunities

Readings that pass or come uncomfortably close to the upper specification limits are easy-to-spot red flags for process concerns. Monitor the process, and investigate whenever a reading is higher than the upper specification limit. There may be special circumstances that cause the upper specification limit to be breached, or there may be common causes in play with an out-of-control process.

Yield improvements through comparing LSL with the mean and USL

Take some time and compare where the upper and lower specification limits compare with the mean. If you see a shift — where one specification limit is much closer to the mean, and one is much farther away — you may have an opportunity to adjust the process that helps raise or drop the mean to a value that is closer to the halfway point between the upper and lower specification limits.

3 upper specification limit best practices

- Verify with the customer that the correct specification level is set. Sometimes it can be expensive and time-consuming to meet the lower specification level, and you might find out that the level was set arbitrarily. You also might find out that the customer does not mind having an even smaller LSL.

- Automate the data collection process as much as possible when collecting data to review. This type of data can require a lot of manpower to collect, yet often there is a technological solution that collects the data for far less time and money.

- Be sure to not only regularly measure processes for specification limits data, but to review that data regularly. Many companies collect this type of information but wait too long between data reviews, resulting in time lost and money spent.

Frequently Asked Questions (FAQ) about lower specification limit

Can I have an upper specification limit that is higher than my upper control limit and still satisfy my customer?

It can be done, but not without an extremely high cost. When a process is not capable, it does not mean all products will fail, but it does show that there will be a large quantity of product that will not meet customer requirements. These products will require rework or scrap. No company would willingly wish to do business this way, which is the entire point of comparing control limits with specification limits.

The short answer is that you do not stay in business long if your lower specification limits are higher than your lower control limits.

All my values are within the upper specification limit, though many are close to the boundary. Is my system still capable?

Yes, it is still considered capable, though the system may not be in control. If you see a lot of values near the specification boundary it is cause for concern. If you can make it so, you always want every value to be the optimal value, with as little variation as possible. Barely passing values today can become out-of-specification values tomorrow.

Can specification limits be used on other charts than the X-bar R chart shown earlier?

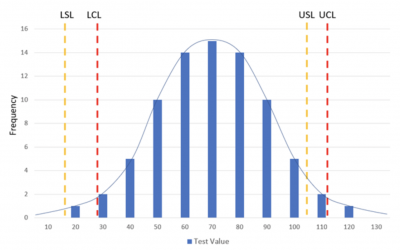

Any chart that can show an upper and lower control limit can also show specification limits. Here’s another example, a histogram, with the limits demonstrated. In this example, since the USL is higher than the UCL, this system is considered not capable.

Upper specification limits

Upper specification limit, or USL, represents the highest limit that a measurement or reading can reach and still be acceptable to the customer. It’s important to compare with the higher control limit to determine if the system is capable of meeting customer expectations over time. Reviewing this regularly will help maintain quality levels, identify future process improvements, and confirm that customer requirements are met.