When you stop a person working on the line and request they rework something so it can be shipped out, do you account for that extra labor, material cost, delays, etc.? If not, then your process has a hidden factory.

We’ll define the hidden factory in the context of cost of poor quality and rolled throughput yield (RTY). The disadvantages and implications of the hidden factory will be explained as well as how to measure and reduce the amount of product being produced in your hidden factory.

Overview: What is the hidden factory?

Many organizations claim their processes are functioning at very high levels of yield. But are they accurately measuring and reporting out their yield levels? Not if they aren’t considering the hidden factory.

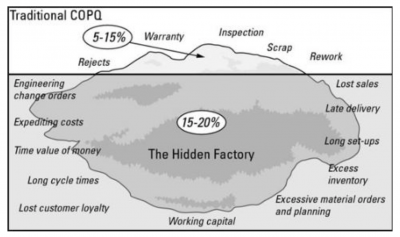

While there are a number of ways to graphically display the hidden factory, the analogy of an iceberg is the most common. Above the waterline, you see the traditional and captured costs of poor quality, such as: rejects, warranty costs, inspection, scrap, and rework. Below the waterline are the hidden costs, which are typically not captured and accounted for.

Armand V. Feigenbaum (1920-2014), an American quality control expert and businessman, devised the concept of Total Quality Control, which led to the development of Total Quality Management. He said the hidden factory can account for anywhere from 20% to 40% of an organization’s total capacity.

Feigenbaum referred to the hidden factory as “that part of your organization that exists to do bad work — not because you want to do bad work, but because the whole process is such that you are driven into it.”

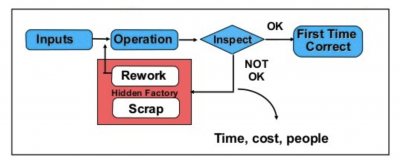

In the graphic below, you can understand why many reports of high yield are deceiving.

You start with an input, which you transform into an output. This output is inspected, and a decision is made whether the output is good or defective. If it is good, the item goes on through the process. If not, an attempt is made to rework it. If that fails, the item is scrapped.

At some point, the item makes it through and continues through the process. But, was the rework and scrap accounted for when determining the yield of the process? Eventually, an item will get through, so your final yield may look good — but at what cost?

First time yield, or first pass yield, is the percentage of the time a product or service passes through a process step without any defects on the first attempt. In most organizations, this value of yield is far less than the reported final yield.

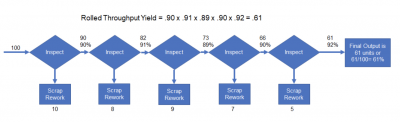

Rolled throughput yield accounts for the hidden factory by not counting the rework and scrap in the calculation of yield. It represents the pure capability of the process to produce defect-free items. It is calculated by multiplying the first pass yield of each process step from the beginning to the end of the process.

Here is an example of the calculations.

Note how well each individual step is doing, yet the final RTY is poor. This would be the yield if all rework and scrap were not counted when calculating yield. The difference between 100% yield and the 61% RTY is the hidden factory.

3 drawbacks of the hidden factory

The name alone signifies the downside of the hidden factory. The hidden factory hides your true yield, and costs are hidden.

1. Feedback loop

Since the activities of the hidden factory are not obvious, there is no immediate feedback loop for correcting process deficiencies.

2. True cost is unknown

If an operator has to work overtime because they had to rework something, the cost of overtime may not be directly attributable to the reworked item.

3. Silo mentality

The hidden factory could be a result of your organization’s silo mentality. How often do your senior finance people visit the factory floor and question excessive inventory levels, process cycle times, process constraints, etc.? Do your manufacturing managers question their departments’ performance if they are within budget?

Why is the hidden factory important to understand?

If you are unaware of the hidden factory, then you don’t have a complete picture of what your process is doing.

Can result in increased costs

The hidden factory consists of rework, scrap, and other costs. If you aren’t tracking these costs, your entire cost structure may not be accurate.

False illusion of performance

Eventually, you will produce enough items to meet your customer demand. You will assume because 1,000 units went into your process and 1,000 came out, your yield is 100%. But what is your true yield if you don’t count the units you scrapped or the ones you reworked? Your true yield is likely less than your reported yield.

Impact on profit

If the hidden costs of your hidden factory could be identified, and steps taken to remove them, the effect on profits could be significant.

Industry examples of the hidden factory

Here is a list of activities you might find being done in your hidden factory.

- Having multiple versions of specifications, increasing the chances of using an outdated version and increasing the time it takes to update the right one.

- Operators reworking parts at their station, taking extra steps that others don’t know about (which causes problems when that operator is away from work or leaves).

- Line supervisors speeding up cycle time to catch up when they’re behind, not realizing it’s causing hidden part damage.

- Sorting mix-ups that allow defective products to reach the customer.

- Lag time in reporting quality data that allows problems to get worse.

- Making it difficult for people to share ideas and improvements with excessive red tape.

- Operators not carrying out preventative maintenance on machines, leading to hidden part damage and future machine failure.

3 best practices when thinking about the hidden factory

The key to managing the hidden factory is to first be aware it exists in your organization. Here are a few tips to managing your hidden factory.

1. Use rolled throughput yield (RTY) to calculate your process yield

Using RTY instead of overall final yield will give you better insight into what your process’ true capability is.

2. Sources of waste

Use the 8 wastes of lean to identify possible sources of waste and rework.

3. Benchmark

If possible, benchmark your key KPIs with best-in-class companies to help identify if you have a hidden factory.

Frequently Asked Questions (FAQ) about the hidden factory

1. What is a hidden factory?

The hidden factory forms when a defective unit is allowed to flow downstream. When the defective is found, a workaround is created, and it is either scrapped or reworked. The effort and costs associated with the workaround are rarely accounted for.

2. How does using RTY impact the hidden factory?

Rolled throughput yield allows you to expose the hidden factory by providing visibility into the yield of each process step. This will help you identify underperforming process steps and give you clues where to look for process improvement opportunities.

3. What is the cost of the hidden factory?

It has been estimated that as high as 40% of the capacity of an organization is wasted by the hidden factory. Research has also indicated this could amount to 15%-25% of an organization’s annual sales.

Let’s shine the light on the hidden factory

The hidden factory consists of the activities required to rework or scrap defective products. Those activities are often not accounted for and remain hidden. The degree of impact of the hidden factory can be revealed by reevaluating how your organization computes its yield calculations. It is not accurate to measure yield using the traditional total input versus the total output of a process since the total output may contain a large amount of reworked units produced in the hidden factory.

By using the rolled throughput calculation instead of the traditional calculation, you will have greater insight into the true capability of your process to produce quality output the first time. The cartoon below sums up the essence of the hidden factory.