A Kano analysis helps you classify your customers’ needs into six categories based on how well you meet their needs versus their satisfaction. Without this understanding, you risk:

- Providing more than your customer really wants or needs

- Exciting the customer in one area, and losing them to competitors in another

- Focusing only on what customers say, not what they think or believe

Let’s explore how to use a Kano analysis to study customer needs. There are several benefits of doing a Kano analysis, and we’ll also share some best practices to gain the needed insight into what your customers are really thinking.

Overview: What is a Kano analysis?

Kano analysis, based on the Kano model developed by Professor Noriaki Kano, is a product and service development and customer satisfaction tool that categorizes and classifies customer requirements and preferences.

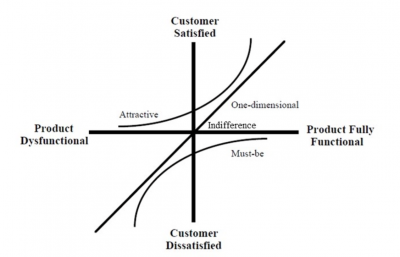

The model is presented as a graph where the vertical axis is degree of customer satisfaction, and the horizontal axis is the degree of functionality or performance. Before proceeding to discuss Kano analysis, let’s cover the basics of the Kano model.

There’s a good deal of variation as to the definition of the four categories of the model, so we’ll use one based on Kano’s original work.

According to Kano, customer preferences or classifications can be defined in terms of four categories:

- Must-be: These are also called basic needs, mandatory, and sometimes dissatisfiers. These are the givens your customer expects. Providing these won’t win you any accolades or increased satisfaction because they are expected. But, not providing these will result in dissatisfaction. A hotel can’t brag that each of its rooms has a bed because your customer expects and requires that. Not having a bed would result in dissatisfaction with the hotel.

- One-dimensional: These needs, sometimes referred to as Performance needs, are based on the premise that more is better, and the more often you provide these, the greater your customer satisfaction.

- Attractive: These are the things that provide the WOW factor and act as Delighters for your customers. They never expected to see that feature or even thought about it. These drive satisfaction up even without a big increase in functionality. The problem with Delighters is that they quickly become Must-bes. What was once a WOW now becomes something we expect every time. That can get expensive over time.

- Indifference: In some cases, the customer may be indifferent to a characteristic. Here, satisfaction doesn’t change regardless of the degree of functionality or how well something is done. This can be represented by the horizontal axis where satisfaction doesn’t change as you go from low functionality to high functionality.

Here is what the Kano model diagram looks like:

Image source: walden-family.com.

Now that you understand the Kano model, let’s see how you can use Kano analysis for diving deeper into the six subcategories you would use to describe your customer needs in greater detail.

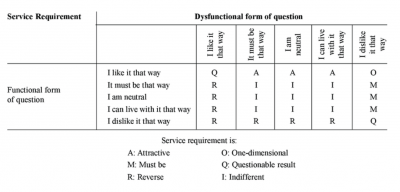

Kano believed the One-dimensional, Attractive, Must-be, and Indifferent categories could be determined by using a questionnaire filled out by the customer. Each question was presented in two ways: How do you feel if that feature is present, and how do you feel if that feature is not present? The customer must respond in one of five ways.

- I like it that way

- It must be that way

- I am neutral

- I can live with it that way

- I dislike it that way

Based on the responses to the two questions, the customer need can be classified into one of six categories.

You are already familiar with the definitions of the original four categories. The other two categories, Questionable and Reversal, indicate there is a contradiction in the customer response (Questionable) or the response was the reverse of what the customer feels (Reversal). Either of these render the response invalid.

The six categories are:

- A = Attractive

- M = Must-be

- O = One-dimensional

- I = Indifference

- R = Reversal

- Q = Questionable

Kano developed a table to identify the final category for each product or service attribute. It is just a matter of finding the intersection of the two responses to the question.

Image source: researchgate.net.

3 benefits of Kano analysis

Knowing your customers’ preferences will help you focus on the things most important to them.

1. Prevent wasted resources

Understanding your Voice of the Customer will prevent you from expending resources chasing attributes that aren’t really important to your customer.

2. Prioritize

This is a good mechanism for prioritizing product and service development to focus on things that will impact your customer satisfaction.

3. Identify what might reduce satisfaction

You may inadvertently design an attribute that will result in negative satisfaction. Your analysis will reveal things that drive satisfaction, are neutral, or even create dissatisfaction.

Why is Kano analysis important to understand?

You need to understand your customers’ preferences even more than they do.

Link to your processes

Once you know the details of your customer preferences, you can link them to the specific processes in your organization that will impact whether you can satisfy them or not.

Timing when a Delighter becomes a Must-Be

By doing a Kano analysis, you will have a heads up as to when your Delighter starts to transition to a Must-Be.

Performing trade-offs

If there are conflicts between what different customers value, you can make decisions to minimize the impact on satisfaction.

An industry example of Kano analysis in action

The sales department came back to the shipping department and reported that their customers would really like their orders turned around and delivered within 24 hours. They claimed that would give them some advantage over the local competition. Everyone agreed this would be a Delighter for the customer.

Unfortunately, shipping was having problems even consistently delivering within 48 hours. To deliver in 24 hours would require some significant process and technology changes.

When the corporate Master Black Belt interviewed a sample of customers and did a Kano analysis, he found out that the 48 hours was a Must-Be, and 24 hours was a Delighter. Since they weren’t even functioning at the basic or mandatory level, he asked, “Why should we invest in delivering a Delighter when we can’t even get the Must-be right?

Senior leadership made the decision to spend the resources on getting all deliveries within the 48-hour timeframe and not to worry about providing 24-hour delivery at that time.

3 best practices when thinking about Kano analysis

Since you’ll be making critical business decisions impacting customer satisfaction, you want to take your time and do your Kano analysis correctly.

1. Ask the customer

You are not the right person to determine what your customer’s preferences are. Get the information directly from them.

2. Focus on the Must-Bes

Get the basics done first. While they may seem boring and less fun than the innovative Delighters, they are, in the long run, your key to success as an organization.

3. Operational definitions

To properly classify preferences, you must have a clear operational definition of your customer’s preferences and what they mean.

Frequently Asked Questions (FAQ) about Kano analysis

What is a Kano analysis used for?

A Kano analysis is used to classify customer preferences for your product or service.

What are the classification categories for a Kano analysis?

Must-Bes, One-dimensional, Attractive, and Indifferent are the basic categories measured on a scale of customer satisfaction and how well your product or service is done. Questionable and Reversal are two other categories you will reveal during your Kano analysis.

Is providing Delighters for my customer always a good strategy?

No. Generally, a Delighter has an incremental cost. If you are the first to market with the Delighter, you will wow your customer… until your competition also offers it. Your Delighter then becomes a Must-Be — usually at an added cost.

To Kano or not to Kano

Kano is a simple yet powerful tool for identifying and classifying customers’ preferences about your product or service. These preferences are Must-Bes (gotta have it), One-dimensional (more is better), Attractive (“wow” factor), Questionable (doesn’t make sense), and Reversal (what? make up your mind).

The degree to which you deliver these preferences will have an impact on customer satisfaction. Knowing this information allows you greater insight into what your customers value so you can work to optimize their satisfaction.