The fundamental premise of the Shainin Red X® process is that for any problem, there is a dominant root cause that must be eliminated or mitigated for the process to be improved. In this article, we will define the Red X process, best practices, and how it can be applied to your organization.

Overview: What is Red X?

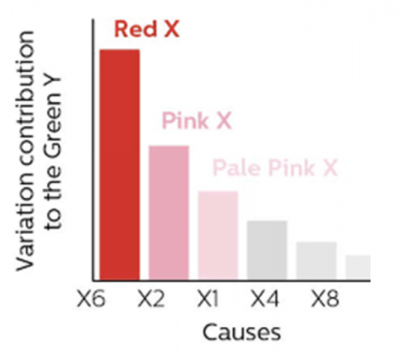

The Red X method is based on the key assumption there is always a dominant cause of variation. This statement is based on the application of the Pareto principle to the causes of the variation. Generally, the variation of the output is caused by the variation of several inputs. These inputs (Xs) are categorized by color, with the Red X being the dominant root cause. Shainin defines the desired state of the output as the GreenY®.

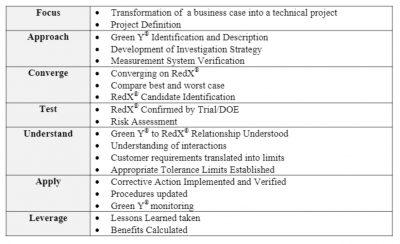

Instead of the DMAIC methodology of Define-Measure-Analyze-Improve-Control, the Red X approach uses the following structure, called FACTUAL:

Shainin Red X FACTUAL approach to problem-solving

An industry example of Red X

The problem was Post Burning Blow Holes on automotive batteries. The post burner is an automatic burning machine designed to weld the cylindrical bushing of an automotive battery to a specified depth of burn. If blow holes are seen on the battery post, then the battery is rejected.

Shainin Red X techniques were used to reduce the percentage of reworks from 0.15% to 0.03%. DOE was used as the primary tool along with:

- Multivari analysis

- Variable search

- Paired comparison

- Component search

- Product / process search

- Scatter plots

3 best practices when thinking about Red X

Here are a few tips on using Red X in your organization.

1. Deep understanding of the process

You must have a deep understanding of the Y and the problem.

2. Problem solving strategy

The Red X approach is very diagnostic in nature. It is the identification, analysis and quick zooming in on the root cause.

3. Measurement System Analysis (MSA)

You must have confidence in the quality of the data captured by your measurement system. This requires you to do a MSA study to validate your data.

Frequently Asked Questions (FAQ) about Red X

1. What are some of the common tools used in Red X?

Two of the most common tools used in Red X are the Solution Tree™ developed by Shainin, Pareto Chart and full factorial design of experiments. Other tools include the Shainin ISO plot, component search, paired comparison, multi-vari chart and BOB/WOW.

2. What do BOB and WOW mean in Red X?

One of the techniques used in Red X is to examine the extremes to try and identify a possible root cause. You will look at the Best of the Best (BOB) versus the Worst of the Worst (WOW).

3. Who developed the Red X approach?

Dorian Shainin (1914-2000) was an American quality consultant, aeronautical engineer, and author primarily noted for his contribution in the field of problem-solving, specifically the creation and development of the Red X concept.

Red X in a nutshell

Red X is a problem-solving technique based on the premise there is one dominant root cause for process variation and problems. Using a convergent process of analysis focusing on potential process input variables (X), the end result will be an identification of the primary Red X root cause along with lesser colors of Pink Xs.