There are a lot of capability indices out there. As you look deeper into process capability analysis, you are going to encounter Cpk, Ppk, Cpm, and more. The good news is that if you already have an understanding of Cpk and Ppk, you already have the know-how to determine initial process capability. This is found with Cmk.

Overview: What is Cmk?

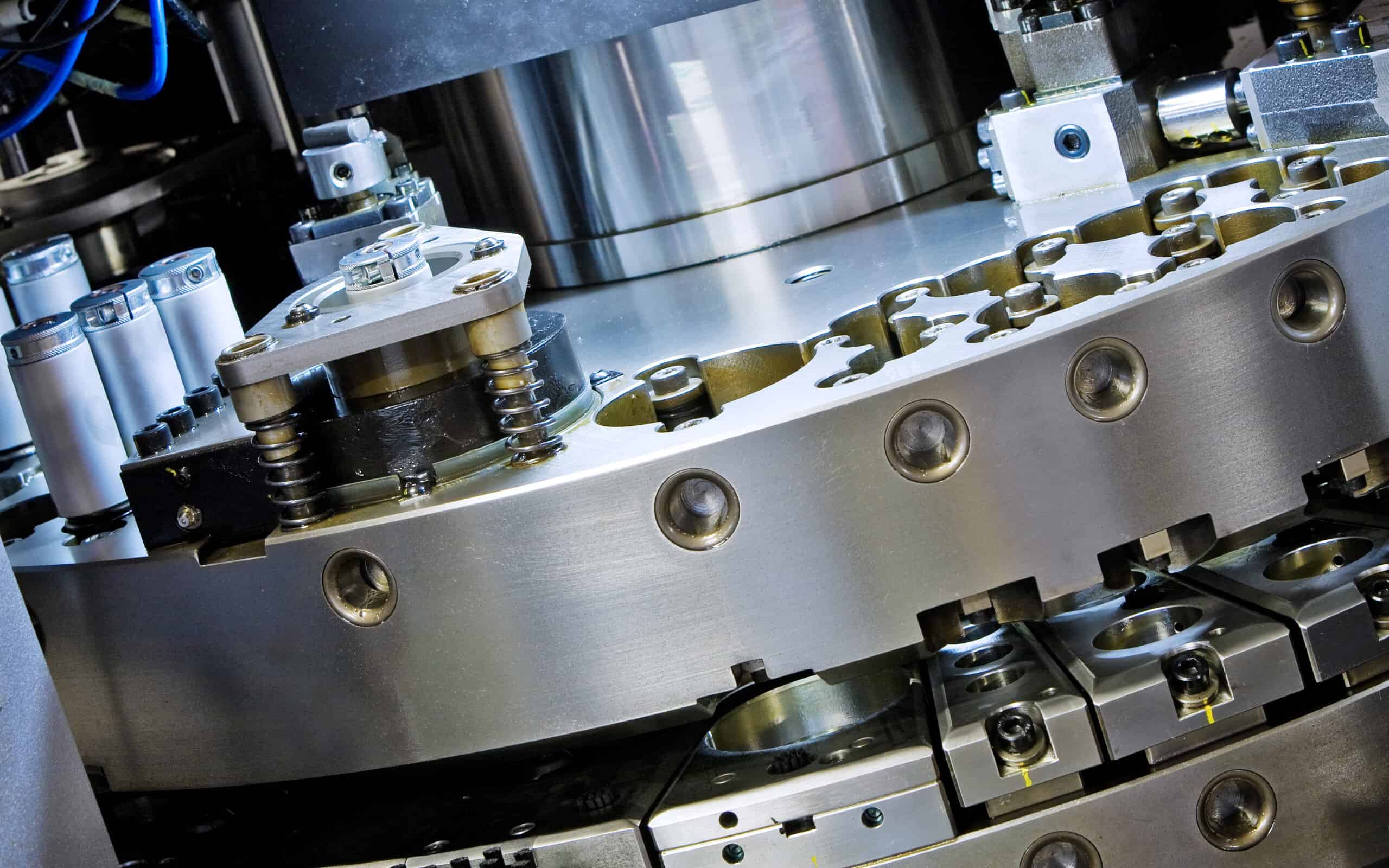

Cmk is a short-term index that is utilized in the determination of the effectiveness of machine improvement efforts or a new machine’s capability to meet requirements in an initial run. It is also known as the Machine Capability Index.

4 benefits of Cmk

There are a few benefits to utilizing Cmk. Let’s go through them:

1. Verification

With the Cmk index, you get verification that a new machine is able to handle the demands of an initial run.

2. Improvement tracking

Utilizing Cmk can be used to authenticate if machine improvements are indeed benefitting processes.

3. Constant checks

While it is a short-term index, Cmk does provide continual checks that verify machines are running at the level that they should be.

4. Trend-spotting

Cmk can be a valuable forecaster and indicator.

Why is Cmk important to understand?

If you are asking yourself why you should know about Cmk, here are some reasons why it is important to understand:

You get a more well-rounded comprehension of capability indices

Capability indices help you meet requirements, focus on continual improvement, and can lead to the betterment of your machines and processes. For these reasons, having a thorough comprehension of them is a major asset.

It lays the groundwork for a long-term index

Prior to you doing a long-term index for checking a machine’s viability, you need to know if it can meet standards on its initial run.

Added peace of mind

Understanding how Cmk works can give you more confidence that a machine can meet standards in the short term.

An industry example of Cmk

A greeting card company has been taking on new corporate clients at a rapid rate. New machines must be brought in so that demand can be met. Three different models have been brought into the factory on a 30-day trial period so that the card company can decide which machine is going to likely work best for them. After doing 50 measurements for each of the three models, it is found that Model C has a Cmk higher than 2.0, while the two others fall below 1.5. Model C is brought on to meet the demands of the new clients.

3 best practices when thinking about Cmk

Here are some good practices when it comes to Cmk:

1. Do your homework

For the results of a Cmk index to be trustworthy, you need to properly plan for it, perform it sufficiently, and evaluate it thoroughly.

2. Use Cmk where it is best served

Cmk is a short-term index that is most ideally suited for the determination of capability in an initial run. Other indices may provide better insight into machine capability over the long term.

3. If you already know other indices, do not be intimidated by Cmk

Cmk follows the same general formula as the more common Cpk and Ppk. If you already have a firm understanding of these, wrangling Cmk should be pretty easy.

Frequently Asked Questions (FAQ) about Cmk

How do I interpret the results of Cmk?

The higher the number, the better the results. Ideally, the number you arrive at should be a minimum of 1.67 or 2.0 to meet industry standards.

How many measurements are taken for a proper Cmk index?

20-50 consecutive measurements are the standard.

What does Cmk stand for?

Cm is the spread of a machine’s performance when compared against the width of the tolerance. The shifting and location and how it relates to the tolerance is represented by k.

Why is Cmk considered a short-term index?

There are multiple factors that can create variations. These are the environment, machine, operator, method, material, and measurement. With Cmk, the only variations that are accounted for are measurement and machine.

Implementing Cmk

By having Cmk as part of your capability index arsenal, you have the ability to determine if a new machine being brought into your business is going to be able to meet standards during an initial run. Having this knowledge can help you make better decisions for your business and save you money.