The DMAIC methodology should be used when a product or process is in existence at your company but is not meeting customer specification or is not performing adequately. For DMAIC milestone reviews, there are certain deliverables, checkpoints, questions and concerns that the Black Belt and improvement team should be aware of prior to a tollgate/milestone review.

In lieu of or in addition to your Master Black Belt tollgate/milestone preparation review, the following Six Sigma DMAIC quick reference sheets can help prepare for your milestone review.

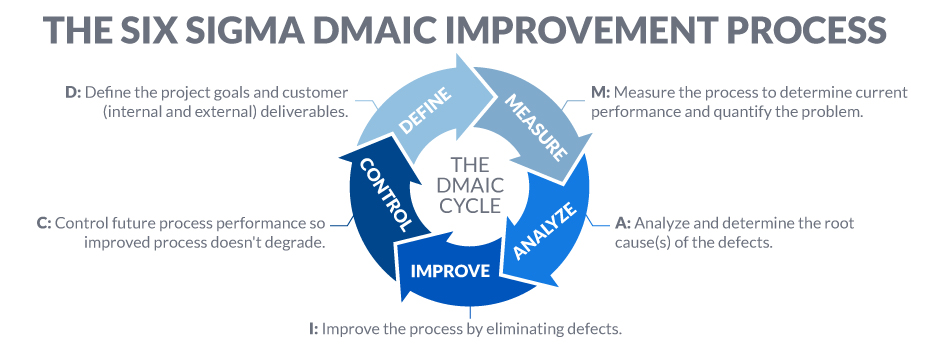

Jump to: Define, Measure, Analyze, Improve, Control

Define Phase

Deliverables Of Phase:

- Fully trained team is formed, supported, and committed to work on improvement project.

- Customers identified and high impact characteristics (CTQs) defined, team charter developed, business process mapped.

Checkpoints For Completion:

Team Readiness

- Team is sponsored by a champion or business leader.

- Team formed and team leaders (MBBs/Coaches and BBs/Project Leads) assigned.

- Improvement team members fully trained on Six Sigma and DMAIC.

- Full participation by members in regularly held team meetings.

- Team members perform project work when assigned and in a timely fashion.

- Team members regularly document their project work.

- Team is equipped with available and reliable resources.

Customers (and CTQs)

- Customer(s) identified and segmented according to their different needs and requirements.

- Data collected and displayed to better understand customer(s) critical needs and requirements.

Team Charter

- Project management charter, including business case, problem and goal statements, project scope, milestones, roles and responsibilities, communication plan.

Business Process Mapping

- Completed, verified, and validated high-level ‘as is’ (not ‘should be’ or ‘could be’) business process map.

- Completed SIPOC representation, describing the Suppliers, Inputs, Process, Outputs, and Customers.

Questions To Determine Appropriate Application:

Team Readiness

- Who are the improvement project team members, including BBs/Project Leads and MBBs/Coaches?

- Has everyone on the team, including the team leaders, been properly trained (on DMAIC)?

- Does the team have regular meetings?

- How often are the team meetings?

- Is there regularly 100% attendance at the team meetings? If not, have appointed substitutes attended to preserve cross-functionality and full representation?

- If substitutes have been appointed, have they been briefed on the project charter and goals and received regular communications as to the project’s progress to date?

- Has the project work been fairly and/or equitably divided and delegated among team members who are qualified and capable to perform the work? Has everyone contributed?

- Are there any constraints known that bear on the ability to perform project work? How is the team addressing them?

- How is the team tracking and documenting its work?

- Is the team adequately staffed with the desired cross-functionality? If not, what additional resources are available to the team?

Customers (and CTQs)

- Has the customer(s) been identified?

- Are there different segments of customers?

- Has the improvement team collected the ‘voice of the customer’ (obtained feedback – qualitative and quantitative)?

- What customer feedback methods were used to solicit their input?

- Have the customer needs been translated into specific, measurable requirements? How?

Team Charter

- Has a team charter been developed and communicated?

- Has the charter changed at all during the course of the project? If so, when did it change and why?

- Does the charter include the following?

– Business Case: What are the compelling business reasons for embarking on this project? Is the project linked to key business goals and objectives? What key business process output measure(s) will the project leverage and how? What are the rough order estimates on cost savings/opportunities on this project?

– Problem Statement: What specifically is the problem? Where does it occur? When does it occur? What is its extent?

– Goal Statement: What is the goal or target for the improvement team’s project? Do the problem and goal statements meet the SMART criteria (specific, measurable, attainable, relevant, and time-bound)? Has anyone else (internal or external to the organization) attempted to solve this problem or a similar one before? If so, what knowledge can be leveraged from these previous efforts? How will the project team and the organization measure complete success for this project?

– Roles and Responsibilities: What are they for each team member and its leadership? Where is this documented?

– Project Scope: What are the boundaries of the scope? What is in bounds and what is not? What is the start point? What is the stop point? How does the project manager ensure against scope creep? Is the project scope manageable? What constraints exist that might impact the team?

– Milestones: When was the project start date? When is the estimated completion date? Is the project currently on schedule according to the plan? Has a project plan, Gantt chart, or similar been developed/completed? How did the project manager receive input to the development of the plan and the estimated completion dates/times of each activity? Is there a critical path to complete the project? How will variation in the actual durations of each activity be dealt with to ensure that the expected project completion date is met?

– Communication Plan: What are the dynamics of the communication plan? What critical content must be communicated – who, what, when, where, and how? When are meeting minutes sent out? Who is on the distribution list? How do you keep key subject matter experts in the loop?

Business Process Mapping

- Has a high-level ‘as is’ process map been completed, verified and validated?

- Has a SIPOC diagram been produced describing the Suppliers, Inputs, Process, Outputs, and Customers?

- Is the improvement team aware of the different versions of a process: what they think it is vs. what it actually is vs. what it should be vs. what it could be?

- Is the current ‘as is’ process being followed? If not, what are the discrepancies?

- Are different versions of process maps needed to account for the different types of inputs?

- How was the ‘as is’ process map developed, reviewed, verified and validated?

- What tools and roadmaps did you use for getting through the Define phase?

Measure Phase

Deliverables Of Phase:

Key measures identified, data collection planned and executed, process variation displayed and communicated, performance baselined, sigma level calculated.

Checkpoints For Completion:

Key Measures Identified

- Key measures identified and agreed upon.

- High impact defects defined and identified in the business process.

Data Collection Planned and Executed

- Solid data collection plan established that includes measurement systems analysis.

- Data collected on key measures that were identified.

Process Variation Displayed/Communicated

- Process variation components displayed/communicated using suitable charts, graphs, plots.

- Long term and short term variability accounted for.

Performance Baseline/Sigma Calculation

- Measure baseline process performance (capability, yield, sigma level).

Questions To Determine Appropriate Application:

Key Measures Identified

- What are the key input variables? What the key process variables? What are the key output variables?

- What key measures identified indicate the performance of the business process?

- What are the agreed upon definitions of the high impact characteristics (CTQs), defect(s), unit(s), and opportunities that will figure into the sigma calculations and process capability metrics?

Data Collection Planning and Execution

- Was a data collection plan established?

- What data was collected (past, present, future/ongoing)?

- Who participated in the data collection?

- How did the team select a sample?

- What has the team done to assure the stability and accuracy of the measurement process?

- Was a gauge R&R conducted?

- Was stratification needed in the data collection and analysis?

Process Variation Displayed/Communicated

- What charts has the team used to display the components of variation in the process?

- What does the chart tell us in terms of variation?

Performance Baseline/Sigma Calculation

- What is the current process performance in terms of it capability indices?

- What is the current process performance in terms of its yield or sigma level(s)?

- How large is the gap between current performance and the customer-specified (goal) performance?

- Have you found any ‘ground fruit’ or ‘low-hanging fruit’ for immediate remedies to the gap in performance?

- What particular quality tools did the team find helpful in getting through the measure phase?

Analyze Phase

Deliverables Of Phase:

Data and process analysis, root cause analysis, quantifying the gap/opportunity.

Checkpoints For Completion:

Data and Process Analysis

- Identify gaps between current performance and the goal performance.

Root Cause Analysis

- Generate list of possible causes (sources of variation).

- Segment and stratify possible causes (sources of variation).

- Prioritize list of ‘vital few’ causes (key sources of variation).

- Verify and quantify the root causes of variation.

Quantifying the Gap/Opportunity

- Determine the performance gap.

- Display and communicate the gap/opportunity in financial terms.

Questions To Determine Appropriate Application:

Data and Process Analysis

- What does the data say about the performance of the business process?

- Did any value-added analysis or ‘lean thinking’ take place to identify some of the gaps shown on the ‘as is’ process map?

- Was a detailed process map created to amplify critical steps of the ‘as is’ business process?

- How was the map generated, verified, and validated?

- What did the team gain from developing a sub-process map?

- What were the crucial ‘moments of truth’ on the map?

- Were there any cycle time improvement opportunities identified from the process analysis?

- Were any designed experiments used to generate additional insight into the data analysis?

- Did any additional data need to be collected?

- What model would best explain the behavior of output variables in relation to input variables?

Root Cause Analysis

- What tools were used to generate the list of possible causes?

- Was a cause-and-effect diagram used to explore the different types of causes (or sources of variation)?

- What tools were used to narrow the list of possible causes?

- Were Pareto charts (or similar) used to portray the ‘heavy hitters’ (or key sources of variation)?

- What conclusions were drawn from the team’s data collection and analysis?

- How did the team reach these conclusions?

Quantifying the Gap/Opportunity

- What is the cost of poor quality as supported by the team’s analysis?

- Is the process severely broken such that a re-design is necessary?

- Would this project lend itself to a DFSS project?

- What are the revised rough order estimates of the financial savings/opportunity for the improvement project?

- Have the problem and goal statements been updated to reflect the additional knowledge gained from the analyze phase?

- Have any additional benefits been identified that will result from closing all or most of the gaps?

- What were the financial benefits resulting from any ‘ground fruit or low-hanging fruit’ (quick fixes)?

- What quality tools were used to get through the analyze phase?

Improve Phase

Deliverables Of Phase:

Generate (and test) possible solutions, select the best solutions, design implementation plan.

Checkpoints For Completion:

Generating (and Testing) Possible Solutions

- Possible solutions generated and tested.

Selecting The Best Solution(s)

- Optimal solution selected based on testing and analysis.

- New and improved process (‘should be’) maps developed.

- Cost/benefit analysis of optimal solution(s).

- Small-scale pilot for proposed improvement(s).

- Pilot data collected and analyzed.

- Improved process (‘should be’) maps modified based on pilot data and analysis.

- Project impact on utilizing the best solution(s).

Designing Implementation Plan

- Solution implementation plan established, including schedule/work breakdown structure, resources, risk management plan, cost/budget, and control plan.

- Contingency plan established.

Questions To Determine Appropriate Application:

Generating (And Testing) Possible Solutions

- How did the team generate the list of possible solutions?

- What tools were used to tap into the creativity and encourage ‘outside the box’ thinking?

Selecting The Best Solution(s)

- What tools were used to evaluate the potential solutions?

- Were any criteria developed to assist the team in testing and evaluating potential solutions?

- What were the underlying assumptions on the cost-benefit analysis?

- Are there any constraints (technical, political, cultural, or otherwise) that would inhibit certain solutions?

- Was a pilot designed for the proposed solution(s)?

- Describe the design of the pilot and what tests were conducted, if any?

- What conclusions were drawn from the outcomes of the pilot?

- What lessons, if any, from the pilot were incorporated into the design of the full-scale solution?

Designing The Implementation Plan

- Is the improvement plan best served by using the DFSS approach?

- What is the implementation plan?

- What poka-yoke or error proofing will be done to address some of the discrepancies observed in the ‘as is’ process?

- What does the ‘should be’ process map/design look like?

- How does the solution remove the key sources of variation discovered in the analyze phase?

- What attendant changes will need to be made to ensure that the solution is successful?

- What communications are necessary to support the implementation of the solution?

- How will the team or the process owner(s) monitor the implementation plan to see that it is working as intended?

- What is the team’s contingency plan for potential problems occurring in implementation?

- How will the organization know that the solution worked?

- What tools were most useful during the improve phase?

Control Phase

Deliverables Of Phase:

Documented and implemented monitoring plan, standardized process, documented procedures, response plan established and deployed, transfer of ownership (project closure).

Checkpoints For Completion:

Monitoring Plan

- Control plan in place for sustaining improvements (short and long-term).

Process Standardization

- New process steps, standards, and documentation are ingrained into normal operations.

Documented Procedures

- Operating procedures are consistent.

- Knowledge gained on process is shared and institutionalized.

Response Plan

- Response plans established, understood, and deployed.

Transfer of Ownership (Project Closure)

- Transfer ownership and knowledge to process owner and process team tasked with the responsibilities.

Questions To Determine Appropriate Application:

Monitoring Plan

- What is the control/monitoring plan?

- How will the process owner and team be able to hold the gains?

- What key inputs and outputs are being measured on an ongoing basis?

- How will input, process, and output variables be checked to detect for sub-optimal conditions?

- How will new or emerging customer needs/requirements be checked/communicated to orient the process toward meeting the new specifications and continually reducing variation?

- Are control charts being used or needed?

- How will control chart readings and control chart limits be checked to effectively monitor performance?

- Will any special training be provided for control chart interpretation?

- Is this knowledge imbedded in the response plan?

- What is the most recent process yield (or sigma calculation)?

- Does the process performance meet the customer’s requirements?

Process Standardization

- Has the improved process and its steps been standardized?

Documented Procedures

- Is there documentation that will support the successful operation of the improvement?

- Does job training on the documented procedures need to be part of the process team’s education and training?

- Have new or revised work instructions resulted?

- Are they clear and easy to follow for the operators?

Response Plan

- Is a response plan in place for when the input, process, or output measures indicate an ‘out-of-control’ condition?

- What are the critical parameters to watch?

- Does the response plan contain a definite closed loop continual improvement scheme (e.g., plan-do-check-act)?

- Are suggested corrective/restorative actions indicated on the response plan for known causes to problems that might surface?

- Does a troubleshooting guide exist or is it needed?

Transfer Of Ownership (Project Closure)

- Who is the process owner?

- How will the day-to-day responsibilities for monitoring and continual improvement be transferred from the improvement team to the process owner?

- How will the process owner verify improvement in present and future sigma levels, process capabilities?

- Is there a recommended audit plan for routine surveillance inspections of the DMAIC project’s gains?

- What is the recommended frequency of auditing?

- What should the next improvement project be that is related to the process?

- What quality tools were useful in the control phase?

Integrating and Institutionalizing Improvements, Knowledge and Learnings

- What other areas of the organization might benefit from the project team’s improvements, knowledge, and learning?

- How might the organization capture best practices and lessons learned so as to leverage improvements across the business?

- What other systems, operations, processes, and infrastructures (hiring practices, staffing, training, incentives/rewards, metrics/dashboards/scorecards, etc.) need updates, additions, changes, or deletions in order to facilitate knowledge transfer and improvements?