While many organizations claim to produce or deliver high-quality products and services, do they understand that it isn’t really free? While Quality is Free is the name of a popular quality book by Philip Crosby, he didn’t mean there was no cost to attain higher quality, but that the investment you make in improving quality will be returned quickly.

Let’s look at what we mean by COQ, the different elements of COQ, its benefits, and how to go about establishing your organization as a leader in quality products and services.

Overview: What is COQ?

The concept of COQ has been around for many years. Famed quality expert Joseph Juran wrote about the concept of quality cost in his 1951 book titled Quality Control Handbook. He defined COQ as having both tangible and intangible costs.

Armand Feigenbaum expanded the concept in his 1956 Harvard Business Review article on Total Quality Control. In that article, he introduced the four quality cost categories that are still the basis today for defining COQ.

Crosby felt that the only performance measure a business should have is COQ. He went on to state that the COQ is the expense of non-conformance. His research over the years showed that most companies will spend between 15%-20% of their annual sales on quality costs. It was his proposition that a well-designed quality system can be implemented at a far lower cost.

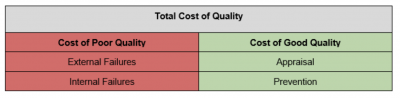

Today, you will hear the concept of COQ associated with a number of different quality cost concepts. Three of the more common ones are total cost of quality, cost of good quality, and cost of poor quality.

Below is a graphic showing the relationship of them along with the four common quality cost categories as defined by Feigenbaum.

Image source: qualitydigest.com.

Let’s define the four cost categories associated with COQ.

- Prevention: Costs associated with those activities intended to prevent your production and delivery of poor-quality products and services.

- Appraisal: Costs that are designed to inspect, test, evaluate, and audit products and services to ensure that your products and services do not contain nonconformances. Note that inspection is considered one of the 8 lean manufacturing wastes.

- Internal failure: Costs of catching, reworking, or scrapping non-conforming items before they’re shipped to your customer.

- External failure: Uh-oh! These are the costs you incur if a non-conforming item is shipped and received by your customer.

Juran created a COQ curve that demonstrates the relationship between quality and COQ. Note how your COQ goes down as a function of improved quality and of spending more on prevention and reducing your internal and external failure costs.

Image source: www.cqeacademy.com.

3 benefits of COQ

The benefits of COQ come from implementing quality systems and applying more prevention rather than detection. If you don’t produce non-conforming product in the first place, you don’t need to worry about your internal and external failure costs.

1. Reduced costs

Producing (and then catching and reworking) non-conforming products is more costly than producing it correctly the first time. Your customer will not pay you twice for the same product if you have to rework it or make another one.

2. Improved customer satisfaction

Nothing will destroy a relationship with your customer faster than continuously shipping them defective products. By investing wisely to reduce your COQ, you will not only have happier customers, but more profits. Remember that you probably have 15%-20% of your sales as your COQ. That’s a lot of opportunity for improving profits.

3. Competitive advantage

Most companies claim to produce or deliver high-quality products and services. Most do it the wrong way by focusing on catching rather than preventing. If you truly have a superior product or service, and your costs are lower due to your lowered COQ, you will have an advantage over your competition.

Why is COQ important to understand?

Most companies believe that producing things of high quality is a costly endeavor. That’s because they don’t fully understand what their true COQ is.

Quality is not free, but it’s worth the investment

There is a mindset in many organizations that achieving high quality is costly. This is a result of people not recognizing the true cost of not delivering high quality. If they could actually account for the true cost of poor quality, they would see that investing in quality systems of prevention will provide one of the highest ROIs they can have.

Inspection is not the way to achieve quality

The third point of Dr. W. Edwards Deming’s 14 Points states that organizations should “Cease dependence on inspection to achieve quality. Eliminate the need for massive inspection by building quality into the product in the first place.”

COQ is a strategic concept, not just for the quality department

The concept of COQ can be applied to any function in the organization. Every function has a process that produces an output. That output goes to a customer — either internal or external. The question is, how do we improve the quality of every process? The additive effect of everyone focusing on lowering the COQ will provide the strategic foundation for becoming a successful organization.

An industry example of COQ

The CEO of a privately held medium-size company recently read an interesting article on COQ in a quality magazine. She was intrigued by the concept and asked her director of quality to dig deep and identify all the possible business costs associated with quality besides the obvious cost of the QC staff, equipment, testing materials, and product that had been scrapped. This included every other function within the organization.

When the list had been compiled, she was shocked. Among the identified COQ items were:

- cost of rework

- additional inventory to make up for defective product

- cost of quarantining product for final disposition

- customer chargebacks for returned product

- expedited freight costs

- disposal costs

- increased safety incidents

- lost customer sales due to product quality issues

- schedule disruptions for remakes

- equipment downtime

- employee overtime to make up for lost production

- overpayment on payables

- underpayment on receivables

- reduced employee morale

She was amazed at how much more there is to COQ than the obvious. Her director of finance estimated that these costs were equal to about 18% of their yearly sales revenue, and most of the costs were not even being tracked on an ongoing basis. She communicated all of this to the rest of the organization and refocused the quality department on preventing defects rather than catching them.

3 best practices when thinking about COQ

There are a number of COQ concepts that, if applied correctly, can help you create a culture that focuses on prevention of defects. Here are a few thoughts on how to do that.

1. Focus on prevention, not detection

Preventing errors is less costly than catching them. The worst-case scenario is that your customer becomes your inspection department, catches all the nonconformances and sends back all your defective products. They won’t be a customer for long.

2. Communicate how high your true COQ is

Once people realize your true COQ can amount to 15%-20% of your annual sales revenue, they will be more sensitized to what the true impact is on the financial health of your organization.

3. Understanding your hidden COQ

Here is a chart showing some of the hidden costs of quality that most organizations aren’t aware of.

Image source: www.qualitydigest.com.

Frequently Asked Questions (FAQ) about COQ

What are the four costs of quality?

The four costs of quality are prevention, appraisal, internal failures, and external failures.

How much is total COQ for most organizations?

It is said that the total COQ of most organizations can range from 15%-20% of annual sales revenue.

Should increased inspection be used to reduce my COQ?

It depends. In the long term, you should focus on the prevention of defects rather than trying to catch the defects you already made. Until such time that you have processes capable of producing a perfect product, you may have to rely on inspection so you don’t send bad products to your customer.

Is quality really free, or is there a COQ?

The concept of COQ tells you that there are four costs of quality: prevention, appraisal, internal failures, and external failures. Your long-term goal is to not produce defective or non-conforming products. You will accomplish this by focusing on prevention.

It is the role of your organization’s leadership to instill a culture of quality. This will improve your profitability and customer satisfaction.