Category: Control Charts

Short-Run Statistical Process Control Techniques

Updated:Short production runs are a necessity in high-mix, low-volume manufacturing environments. The trend in manufacturing has been toward smaller production runs, with production runs – as well as products – tailored to the individual customer’s needs. Although this minimizes inventory and improves responsiveness to the customer, it complicates the application of statistical process control (SPC). Classical […]

Read more »

Common Cause vs. Special Cause Variation: What’s the Difference?

Updated:What is Common Cause Variation? Common cause variation is the kind of variation that is part of a stable process. These are variations that are natural to a system and are quantifiable and expected. Common cause variations are those that are predictable, ongoing, and consistent. Major changes would typically have to be made in order […]

Read more »

Variable vs. Attribute Data: What’s the Difference?

Updated:What is Variable Data? Variable data is any kind of information that is represented and recorded as measurements. The term is often used when discussing the creation of control charts for the purpose of process analysis. Variable data is quantitative, which means it can be described with numerical value and can change along a perpetual […]

Read more »

Assessing Process Stability: Techniques and Tools

Updated:Have you ever wondered why your doctor may keep you waiting in the waiting room or why you have to fast before doing a blood test? Let’s see if Lean Six Sigma can give you an answer.

Read more »

Understanding Exponentially Weighted Moving Average for Time Series Analysis

Updated:Does your data from yesterday represent the current state of your process better than that from a month ago? How can you place more emphasis on it yet still make use of older data? That’s what the Exponentially Weighted Moving Average does.

Read more »

Out of Control Action Plan: Correcting Process Variants for Optimal Performance

Updated:Out-of-control Action Plans (OCAPS) are a piece of the Lean Six Sigma methodology that is often overlooked. Though they have been phased out in some organizations, it is important to understand their purpose and how they can help a company improve its processes.

Read more »

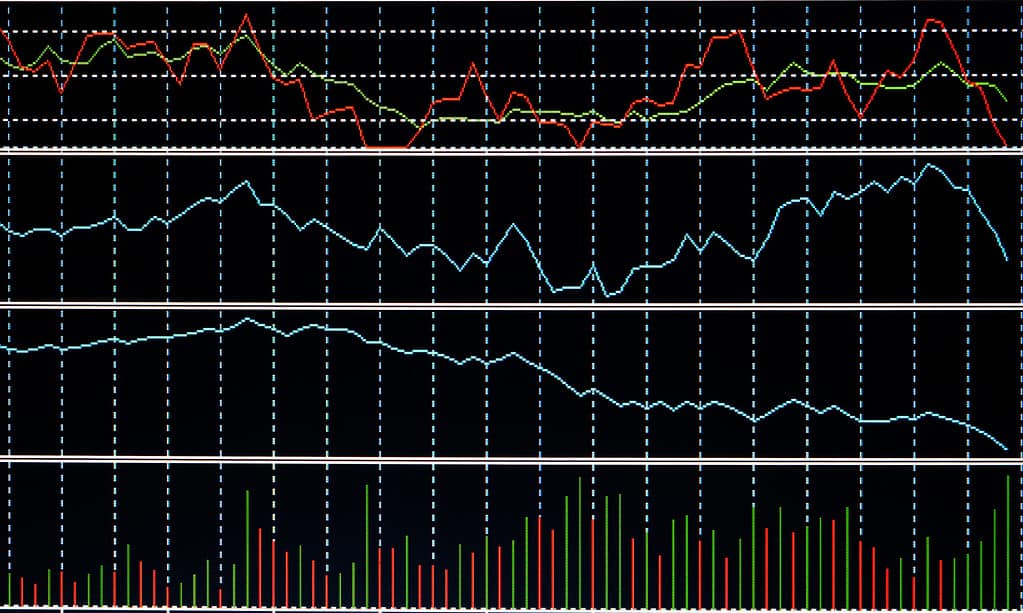

Trend Charts in Quality Management: Enhancing Process Monitoring

Updated:You can learn a lot about your process by monitoring its change over time. There are different trend charts which will allow you to do that. Let’s look at a few.

Read more »

Control Charts and Employee Engagement Helped This Company Save Over $150,000 in One Year

Updated:Providing the proper organizational environment for engaging people in your continuous improvement effort will provide large benefits for your organization. In this study, we look at how the combination of using control charts and providing an environment for people engagement helped one company achieve significant financial benefits. Control charts are a powerful tool for understanding […]

Read more »

Think Outside the Box Plot

Published:A box plot may seem like a simple tool, but as this example shows it can help reveal common and special cause variation that may not have otherwise been noticed. Be sure you’re looking below the surface to optimize your performance!

Read more »

Using Voice of the Process to Identify Critical Processes for Improvement

Updated:Are you hearing voices? If it’s in a business context, then there is nothing to worry about — and it might even be a good thing. Let’s listen in to the voice of the process and hear what it has to say.

Read more »

Quality Control Just Got Easier: Learn How to Use U Charts

Updated:A U chart is one of four quality control charts that engineers use to track variation in a manufacturing process. The other three typical quality control charts are the p chart (which plots the proportion of defective items, the c chart (which shows the number of defects), and the np chart (which shows the number […]

Read more »

Predicting Success: A Comprehensive Guide to Trend Analysis Tools

Updated:Do you possess a crystal ball to see what the future brings for your organization? Probably not, but you do have a statistical version of a crystal ball by using trend analysis.

Read more »

Using Subgrouping to Monitor Process Performance

Updated:When you speak of subgrouping, it is usually in the context of constructing a control chart. Let’s explore the topic in a little more detail. Subgrouping is a technique used in control charts to group data into smaller, more manageable sets or subgroups. The purpose of subgrouping is to increase the sensitivity of the control […]

Read more »

Improving Process Efficiency with Statistical Process Control

Updated:Do you want to know whether your process is in control or not? Statistical Process Control, or SPC, is the tool you want to learn about, so let’s get started.

Read more »

Assessing Process Performance: The Value of Establishing Baselines

Updated:How do you know if your diet is working? You need to start with a baseline and then measure change from that. You should do the same for all your processes. From that process baseline, you can know whether your process is getting better, worse, or not changing. The term “process baseline” typically refers to […]

Read more »

Maximizing the Benefits of In-Control: Tips for Process Improvement

Updated:In-control is not referring to the behavior of your children. It’s about whether your process is exhibiting common or special cause variation. Let’s explore how this works.

Read more »

The Impact of Key Business Issues: Understanding and Addressing Critical Challenges

Updated:Are all your organization’s problems and issues of equal importance? Probably not. How should you handle those that are the most critical and important? Let’s find out. A Key Business Issue (KBI) refers to a critical problem or challenge that your organization faces, which can significantly impact your performance, growth, or competitiveness. KBIs are specific […]

Read more »

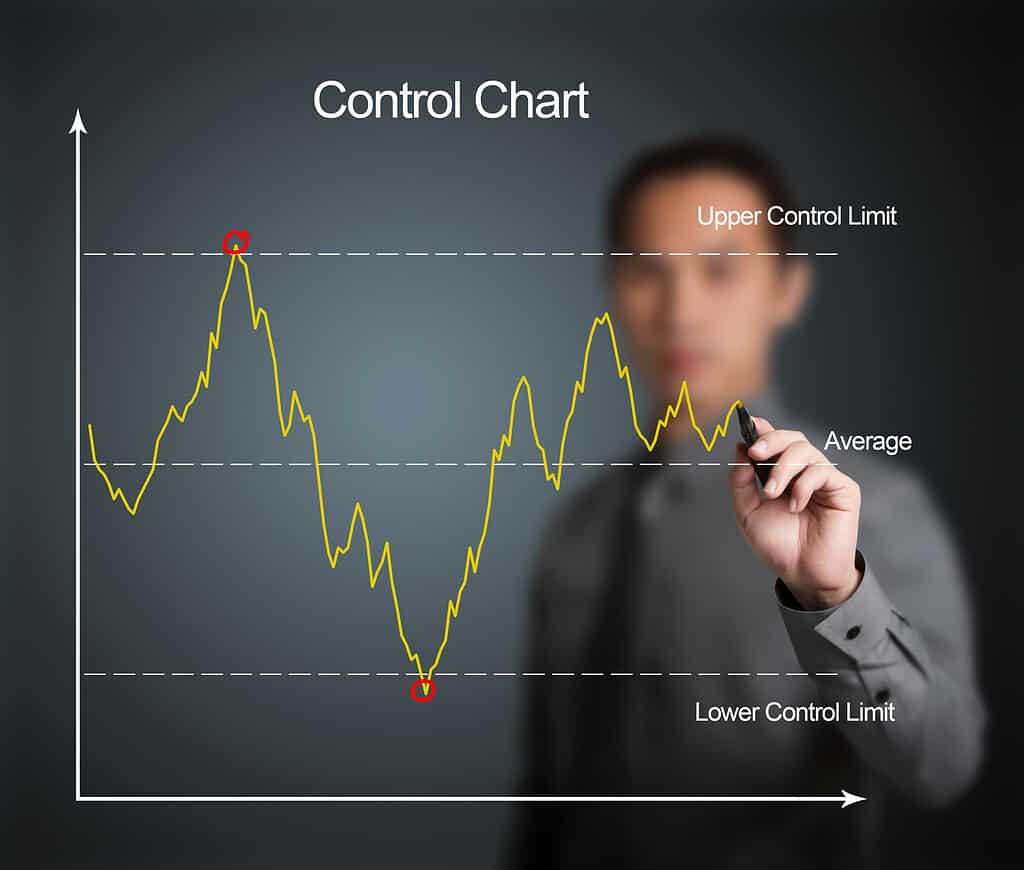

Monitoring Process Stability with Control Charts

Updated:Since there is variation in all processes, how can you tell whether the variation is due to random expected variation, or something unexpected? The control chart is a tool for making that distinction. Let’s learn how that is done.

Read more »

Streamlining Six Sigma Projects with The 7 QC Tools

Updated:The seven basic tools in my home tool chest are a hammer, screwdriver, wrench, saw, drill, pliers, and duct tape. What basic QC tools do you have in your continuous improvement tool chest? Let’s check it out.

Read more »

Run Charts: A Simple and Powerful Tool for Process Improvement

Published:The run chart is a powerful, simple and easy-to-use process improvement tool. Often, the run chart is shortchanged as the statistical tests that can be used with run charts are overlooked. This article takes the reader through the benefits of a run chart as well as how to correctly create and analyze one. A process […]

Read more »

Using Control Charts or Pre-control Charts

Published:Every process falls into one of four states: Ideal: produces 100 percent conformance and is predictable Threshold: predictable but produces the occasional defect Brink of chaos: not predictable and does not produce defects Chaos: not predictable and produces defects at an unacceptable rate Processes tend to migrate toward chaos if not effectively managed. Pre-control Charts […]

Read more »

Manage Control Limits When Implementing Statistical Process Control

Published:Statistical process control (SPC) is the application of statistical methods to identify and control the special cause of variation in a process. Control charts, in theory, are used in product and process development to analyze processes. When a process is shown to be in control in both an average and range chart the process can […]

Read more »

Multivariate Control Charts: T2 and Generalized Variance

Published:Multivariate analysis techniques may be useful in statistical process control (SPC) whenever there is more than one process variable. Multivariate control charting is usually helpful when the effect of multiple parameters is not independent or when some parameters are correlated. This article focuses on parameters that correlate when the Pearson correlation coefficient is greater than […]

Read more »

Go Beyond Control Chart Limitations to Predict and Improve Processes

Published:Article authors, participants in discussion forums and even software documentation claim that any data and especially time-sequenced data are useful only if they are homogeneous – that is, only if they display control chart stability (CCS).1,2,3,4 According to one quality control expert, Donald J. Wheeler, when out-of-control signals occur, “all of our computations, and all of […]

Read more »