Category: Lean

What Is Lean Manufacturing?: Delivering Quality to Your Customers

Published:Lean management – often called “Lean Management,” “The Toyota Way” or simply “Lean” – is a systematic method for waste minimization and process improvement in any type of service or manufacturing

Read more »

Heijunka: The Art of Leveling Production

Published:Heijunka (pronounced hi-JUNE-kuh) is a Japanese word that means “leveling.” When implemented correctly, heijunka elegantly – and without haste – helps organizations meet demand while reducing while reducing waste in production and interpersonal processes. According to many Lean experts, heijunka is better achieved as a later-stage implementation in a Lean organization, long after value […]

Read more »

The Harada Method: Templates to Measure Long-term Goal Achievement – Part 2 of 2

Published:The Harada method helps individuals achieve self-reliance which in turn facilitates a company’s process improvement journey. Part One provides an overview of the method and its genesis. Subsequently, part Two presents five templates to use to plan a goal, measure the goal’s progress, and assess success. An example helps illustrate their practical use. […]

Read more »

Understanding the Concept of Quality

Published:Quality is one of those words and concepts that have many meanings. Let’s review the concept and discuss the different definitions associated with the term. It refers to the degree of excellence or superiority of something, often concerning its intended purpose or function. Further, it is a measure of how well something meets […]

Read more »

How to Foster a Culture of Innovation and Agility in Startups

Published:In today’s fast-paced, technology-driven world, fostering a culture of innovation and agility is essential for startups that want to stay competitive. Startups thrive on innovative ideas, quick pivots, and the ability to adapt to change. This 2014 article raised awareness of Lean Startups. But creating an environment where continuous improvement and creativity flourish […]

Read more »

Case Studies: Startups That Scaled Using Lean Methodologies

Published:Lean Startup methodologies have revolutionized the way modern entrepreneurs approach launching and scaling their businesses. At the core of Lean Startup is the idea of minimizing risk through rapid experimentation, customer feedback, and iterative development. This approach enables startups to efficiently test their business models and products with minimal resources while remaining adaptable […]

Read more »

Application of Lean Six Sigma to the EHS Function of an Organization

Published:Lean Six Sigma (LSS) is a structured approach that combines two powerful process improvement methodologies: Lean, which focuses on eliminating waste, and Six Sigma, which focuses on reducing variation and defects. When applied to the Environmental, Health, and Safety (EHS) function of an organization, Lean Six Sigma provides a robust framework for driving […]

Read more »

Pivoting: When and How to Shift Your Startup Strategy

Published:In the fast-paced world of startups, flexibility is crucial. Entrepreneurs often enter the market with bold ideas, but reality has a way of testing those ambitions. As conditions change, so must the strategies. This adaptability is known as a pivot—a fundamental shift in a startup’s business model, product offering, or market approach. Pivoting […]

Read more »

MVP (Minimum Viable Product): From Concept to Reality

Published:In the world of startups and product development, the Minimum Viable Product (MVP) has become a cornerstone of agile innovation. An MVP is a product with just enough features to attract early adopters and validate a product idea. It allows businesses to test their hypotheses and gather valuable feedback without expending excessive resources. […]

Read more »

Use a Classification and Regression Tree (CART) for Quick Data Insights

Updated:In the Analyze phase of a DMAIC (Define, Measure, Analyze, Improve, Control) Six Sigma project, potential root causes of variations and defects are identified and validated. Various data analysis tools are used for exploratory and confirmatory studies. Descriptive and graphical techniques help with understanding the nature of data and visualizing potential relationships. Statistical analysis techniques, […]

Read more »

Use Multiple Process Improvement Methodologies to Strengthen Results

Updated:There are many process improvement methodologies – Six Sigma/DMAIC (Define, Measure, Analyze, Improve, Control), Lean, Design for Six Sigma (DFSS) and innovation to name merely a few. But with so many choices, it makes applying an improvement methodology difficult. There are questions such as: “What makes this toolset unique?” and “Which one should I be […]

Read more »

Lean Six Sigma Transformation: Harnessing DMAIC to Enhance Operational Efficiency and Customer Satisfaction at Avon

Updated:Efficiency, Elegance, and Empowerment: Avon and Lean Six Sigma Unite In the bustling world of cosmetics, where beauty meets business, one name has stood the test of time, captivating hearts and empowering women for over a century: Avon. From its humble beginnings as a perfume company in the late 19th century to its global presence […]

Read more »

Six Sigma vs. Lean: What’s the Difference?

Updated:What is Six Sigma? Six Sigma is a quality control methodology that is utilized to improve processes through the elimination of defects. In practice, the methodology incorporates project management, analysis, and statistics to improve the functionality of a business by addressing defects in a process. The cornerstone of the Six Sigma method is the DMAIC […]

Read more »

How One Company’s Investment in Employees Led to $40K in Savings

Updated:In business, when times get tough, the knee-jerk reaction is to have layoffs. What follows is a remarkable example of one company that decided to make a further investment in its people by getting them trained toward Six Sigma Green Belt certification and having them put their focus on saving money for the organization. Even […]

Read more »

What is the Best Lean Six Sigma Training and Certification?

Published:Getting recommendations from others for your Lean Six Sigma training and certification is a good strategy. But given all the variation in available programs, it is a good idea to have a list of criteria to compare your recommendations. Here is a list to get you started. What is the best Lean Six Sigma training […]

Read more »

What is the Impact on my Compensation if I am Lean Six Sigma Trained and Certified?

Published:Taking Lean Six Sigma training and getting certified will cost you time and money. Is it worth it? Will you earn more money with the additional credential of a Lean Six Sigma belt? Let’s check it out.

Read more »

What is the Cost of Lean Six Sigma Training and Certification?

Published:If you are being Lean Six Sigma trained and certified by your employer, the cost should not be a concern for you. But what if you must pay for it by yourself? Cost may then be important. Let’s explore the variation in cost for being LSS trained and certified.

Read more »

Lean Six Sigma Training and Certification: Online or in Person?

Updated:Do you like to take classes in a physical classroom or virtually on a computer? This is a significant decision since Lean Six Sigma training and certification can be achieved either way. Let’s examine the plus and minus of each format.

Read more »

Why is Lean Six Sigma Accredited Training and Certification Important?

Published:Would you be happy if your doctor received her MD from an unknown and unaccredited medical school? Probably not. What about your CPA or attorney? Again, probably not. For the same reason, your employer wouldn’t be happy with your Lean Six Sigma certification if it was awarded by an unknown organization with a poor reputation […]

Read more »

What is Lean Six Sigma Training and Certification?

Published:There are two steps to earn a martial arts belt. First, you must be trained in the various techniques and then you must demonstrate your skills and knowledge. The same holds true for Lean Six Sigma training and certification. Let’s learn a little more. What is Lean Six Sigma training and certification? In martial arts, […]

Read more »

How Can I Get Lean Six Sigma Trained and Certified?

Published:When there are too many items on a menu you can get confused by the variety of choices. Getting Lean Six Sigma trained and certified can also be confusing. Let’s discuss some of your options.

Read more »

Using Kanban to Streamline Processes and Improve Efficiency

Updated:Kanban is a tool used in Lean Manufacturing to visually manage the workflow through your processes. It is based on the concept of a pull system where things are only replaced as they are consumed.

Read more »

Failure Fuels Better Results from Lean

Published:Most Lean initiatives fail. What can you do about that? Ensure your organization’s leaders are champions for the deployment who encourage failure as part of your Lean journey.

Read more »

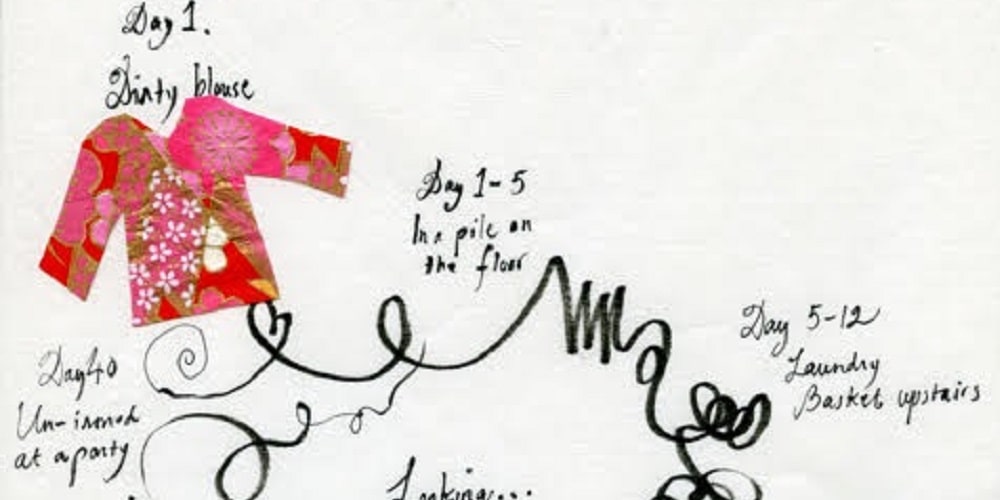

Apply Lean to Save the Planet and Your Marriage

Published:You’ve used Lean principles at work, but can it also work at home? One family implemented Lean in their daily lives over the course of a year with sustainable and measurable results. You can do it, too.

Read more »