Category: Design of Experiments (DOE)

Kienle + Spiess Tackles Welding Issues with Lean and Six Sigma Integration

Updated:Kienle + Spiess is a German mechanical engineering company that was looking to strengthen its welding division by reducing its rework and improving its quality. To accomplish this, the organization utilized a dual approach where Six Sigma and Lean methods work in tandem. Kienle + Spiess was able to practically eliminate shoddy splatter from the […]

Read more »

How Six Sigma and the DMAIC Process Made Samsung Into an Industry Leader

Updated:With strategic implementation, Six Sigma can do wonders for an organization. The methodology can drastically improve processes, cut down on waste, and even help provide better results in the design and R&D of new products. Samsung found that it was having issues with all of the above and, in 1999, conducted a complete overhaul of […]

Read more »

How Design of Experiments (DOE) Helped a Pharma Company Extend Product Shelf Life

Published:Through the use of Design of Experiments (DOE), a pharmaceutical company was able to extend the shelf life for one of its life saving liquid oncology medicines. Let’s see how this saved the company money, lowered the price of the drug and helped save lives.

Read more »

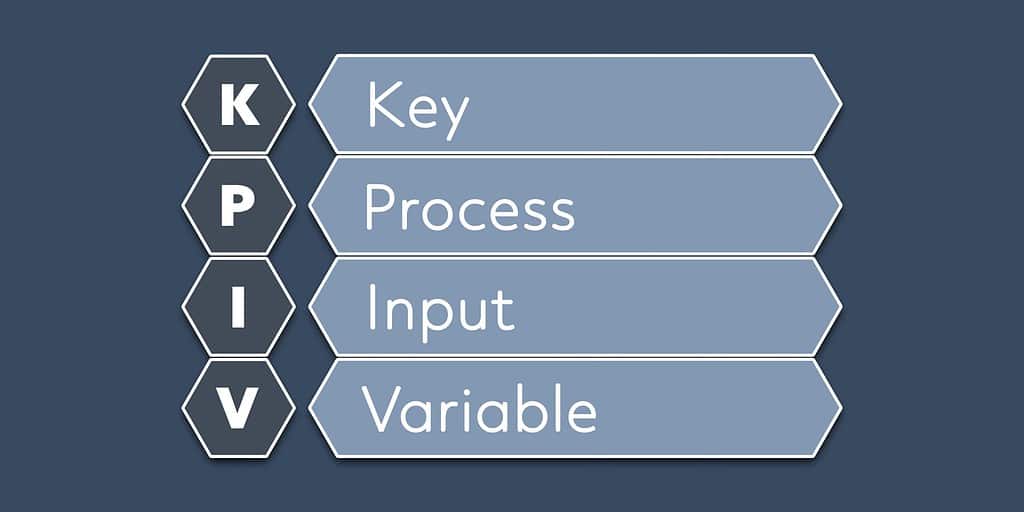

Leveraging Key Process Input Variables for Success

Updated:Complex products and processes can often yield significant variation in output, with resultant poor customer satisfaction, especially when process inputs are not well controlled. By understanding and controlling our key process input variables, we have the perfect approach to keep output variation in check.

Read more »

Exploring the Benefits of Fractional Factorial DOE

Updated:Fractional factorial DOE is a cost- and time-effective designed experimentation statistical tool for understanding the impact of your process inputs on your process outputs.

Read more »

Full Factorial Design: Understanding the Impact of Independent Variables on Outputs

Updated:Full factorial DOE is one of the most powerfully designed experimentation statistical tools for understanding the impact your process inputs have on your process outputs.

Read more »

Maximizing Efficiency and Accuracy with Design of Experiments

Updated:A design of experiments (DOE) is a set of powerful designed experimentation statistical tools for understanding the impact that varying your process inputs will have on the outputs of your process.

Read more »

Case Study: Using DFSS and DOE to Increase Product Reliability

Published:A medical devices company, developing technology to enable smaller medical devices, launched a substrate development effort as part of a larger-scale technology and product development effort. The substrate development effort involved predicting the stress caused by the laser welding process to ensure product reliability. In this Design for Six Sigma (DFSS) case study, design and […]

Read more »

When and How to Use Plackett-Burman Experimental Design

Published:Plackett-Burman experimental design is used to identify the most important factors early in the experimentation phase when complete knowledge about the system is usually unavailable. Developed in 1946 by statisticians Robin L. Plackett and J.P. Burman, it is an efficient screening method to identify the active factors using as few experimental runs as possible. In […]

Read more »

Design of Experiments to Optimize Any Process or Product [VIDEO] – With Mark Kiemele

Published:As the saying goes, if all you have is a hammer in your toolbox, everything looks like a nail. But if you had a torque wrench or a power drill with a box of bits, you are likely to be much more effective. Design of experiments (DOE) is one of those specialized and sophisticated tools […]

Read more »

Optimize Attribute Responses Using Design of Experiments

Published:The objective of a design of experiments (DOE) is to optimize the value of a response variable by changing the values, referred to as levels, of the factors that affect the response. Although often a response is continuous in nature, there are some cases in which the response falls in the attribute category (e.g., pass/fail, […]

Read more »

Design of Experiments – A Primer

Published:Design of experiments (DOE) is a systematic method to determine the relationship between factors affecting a process and the output of that process. In other words, it is used to find cause-and-effect relationships. This information is needed to manage process inputs in order to optimize the output. An understanding of DOE first requires knowledge of […]

Read more »

Reducing Variability with DOE – A Case Study on Propagation of Error (POE)

Published:The Therabath paraffin therapy bath (pictured below) is a durable medical device that holds one gallon of molten paraffin wax. Sufferers of osteoarthritis use it for physical therapy. They dip their hands repeatedly in the heated bath, which helps loosen stiff joints. The wax then slowly solidifies as a glove, producing further therapeutic benefits via […]

Read more »

Design of Experiments for Software Testing

Published:When DOE (design of experiments) is used for software testing, there is a large amount of savings in testing time and cost. Various users in automotive, telecommunication and defense industries report big productivity improvements to their traditional testing methods. This success is due to two major important factors: 1) focused attention on the usage of […]

Read more »

Most Practical DOE Explained (with Template)

Published:For purposes of learning, using, or teaching design of experiments (DOE), one can argue that an eight run array is the most practical and universally applicable array that can be chosen. There are several forms of and names given to the various types of these eight run arrays (e.g., 2^3 Full Factorial, Taguchi L8, 2^4-1 […]

Read more »

Three Romeos and a Juliet – An Early Brush with DOE

Published:Three young men, each being infatuated with the same woman, agree to conduct a design of experiment (DOE) of love. Statistics and romance intertwine in this entertaining and educational real-life story. Which bachelor will end up with the young lady’s hand? Will the DOE prove successful? Peeping into my youthful past, I recall three close […]

Read more »

Save Time With Fractional Factorial DOEs

Published:Design of experiments (DOE) is a key tool in the Six Sigma methodology. DOEs help improve processes in a quantum fashion, and is an approach for effectively and efficiently exploring the cause and effect relationship between numerous process variables (Xs) and the output or process performance variable (Y). DOE helps in the following ways: The […]

Read more »

Reducing Variability With DOE

Published:Six Sigma is the new rallying cry for quality improvement in the process industry. For example, Dow aims to generate an extra $1.5 billion per year in profits after training 50,000 of their employees on the methods of Six Sigma.3 Statistical tools play a key role in achieving savings of this magnitude. In fact, sigma […]

Read more »

Designing and Analyzing Experiments with Mixtures

Published:In the development phase of Design for Six Sigma (DFSS), practitioners who work in domains such as medical devices, pharmaceuticals, foods, material composition and semiconductors frequently deal with experiments to determine optimal ingredient mixtures for desired products. The factors in a mixture experiment are the ingredients or components of a mixture, and the response is […]

Read more »

Design of Experiments/Conjoint Analysis in Marketing

Published:The application of Six Sigma to marketing should be the most obvious use in the world. Where else does there exist such a direct connection between the wants and needs of the customer and the products or services a company offers? However, at first glance, there would seem to be very little hard reliable data […]

Read more »

DOE in Software Testing: The Potential and the Risks

Published:Testing software is hard work. Many aspects of software systems are difficult or impossible to observe and measure directly. That makes finding defects, characterizing performance and estimating reliability the toughest parts of the development process. While there are no silver bullets (and no “lead bullets” either, as per Dr. Barry Boehm, noted software engineering professor […]

Read more »

Give Trainees DOE Experience with Simulated Experiments

Published:Design of experiments (DOE) is an important tool for driving improvement, but experimentation can be an expensive endeavor. Through simulations, new Belts can get hands-on training while learning the challenges of DOE before they apply it to costly real-world experiments.

Read more »

Analyzing Experiments with Ordered Categorical Data

Published:Six Sigma projects in various industries often deal with experiments whose outcomes are not continuous variable data, but ordered categorical data. Analysis of variables (ANOVA) is a technique used to analyze continuous experimental data, but is not adequate for analyzing categorical experimental outcomes. Fortunately, many other methods have been developed to deal with categorical experiments, […]

Read more »

Role for Design of Experiments in Financial Operations

Published:Most Master Black Belts would probably cite design of experiments (DOE) as the most underused statistical tool in financial services. Yet, designed experiments are a favorite tool of statisticians and Six Sigma practitioners working in general business environments because they are an extremely efficient way of identifying what matters in a process and what does […]

Read more »