Category: Control Charts

Leverage Six Sigma to Manage Operational Risk in Financial Services

Published:The recent spate of events such as rogue trading losses, flash trades and a seeming outbreak of Ponzi schemes has made many in financial services wary about their existing risk management practices. In post-financial crisis times, financial services companies are already under pressure to cut their operational costs while also being expected to comply with […]

Read more »

The Complete Guide to Understanding Control Charts

Published:Control charts have two general uses in an improvement project. The most common application is as a tool to monitor process stability and control. A less common, although some might argue more powerful, use of control charts is as an analysis tool. The descriptions below provide an overview of the different types of control charts […]

Read more »

Manage Project Performance with EVM and Control Charts

Published:This article introduces the concept of earned value management (EVM) indexes, a project assessment technique, and control charts, a statistical tool for monitoring variation in a process, and describes how both may be used in tangent to capture more insight from project performance. What to Know About EVM Indexes EVM is a project management technique […]

Read more »

Understanding Statistical Process Control [VIDEO] – With Eduardo Santiago

Published:Statistical process control (SPC), despite sounding esoteric, is a subject that every process owner and worker should – and can – understand, at least at a high level. Knowing whether a process is in control and stable is paramount to producing a product or service that meets customer needs. In this hour-long Minitab training course […]

Read more »

Specification Limits: Proceed with Caution

Published:A true control strategy should be aligned with the process’s statistically based control limits.

Read more »

Should You Use a Mean or Individuals Control Chart?

Published:To plot individual data or to group the data and plot the mean on a control chart, that is the question. Several authors (not including Shakespeare) have weighed in on this issue and I want to present their arguments and then my own. First, let us assume that the process conditions are such that using […]

Read more »

Recalculating Control Limits

Published:From tedious time consuming task to opportunity for improvement. When applying control charts it is common practice to establish the control limits based on the process capability study and then use fix limits on the chart during production. This method is also frequently applied in SPC software programs. The advantage of using fixed limits is […]

Read more »

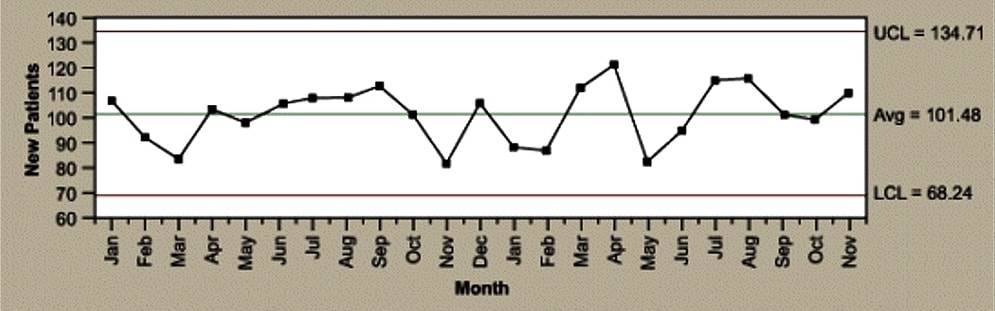

Why Control Chart Your Processes?

Published:Control charting is a tool used to monitor processes and to assure that they remain in control or stable. Proposed by Walter Shewart in 1924, control charts help distinguish process variation due to assignable causes from those due to unassignable causes. Table 1: Types of Process Variation Found on a Control Chart Types of Variation Variation […]

Read more »

From Quality Control to Quality Improvement

Published:Everybody is familiar with control charts for quality control. An example of a control chart is shown below. In the example a packaging company who made blisters for the pharmaceutical industry found the process average for a critical characteristic was out of control. There were some ideas about possible causes but, as in most other […]

Read more »

When to Recalculate Control Limits

Published:A problem that has often confronted practitioners using control charts is when to consider recomputing the control limits. I’ve asked this question to several experts and researched it in numerous SPC texts. Oddly, either the issue is ignored or there is no clear answer to this important question. So I’ll offer my recommendation in this […]

Read more »

Make Valid Control Chart and Subgroup Assumptions

Published:Six Sigma practitioners often state that Six Sigma is not about learning statistics, but is instead about understanding which tool to apply to each situation and how to properly interpret the results. We will attempt to understand the meaning of this statement in four real world examples I have experienced in industry. Control Charts Subgrouped […]

Read more »

Non-normal Data Needs Alternate Control Chart Approach

Published:Some practitioners mistakenly believe that it is not necessary to transform data before creating an individuals control chart when the underlying process distribution response is not normal. An individuals control chart, however, is not robust to non-normally distributed data. Therefore, it is important to use an alternate control charting approach. Necessary Transformation Consider a hypothetical […]

Read more »

A Roadmap for Using Time-weighted Control Charts

Published:Selecting the right type of control chart is a vital starting point for statistical process control (SPC). Which chart to use depends mainly on the classification of the data, the type of underlying distribution and the intent of the application. Selecting the wrong type can result in many false alarms, leading to expensive and fruitless […]

Read more »

The Impact of Control Strategies on Z Shift Values

Published:When the principles of statistical process control (SPC) are used to manage a business or manufacturing process, any indication of the process going out of control will prompt some action on the part of the process owner. When it is well used, SPC will detect shifts in the process due to issues such as tool […]

Read more »

Integrating SPC and SQC to Overcome Weaknesses in Each

Published:Statistical quality control (SQC) and statistical process control (SPC) are two powerful tools, which have different goals and requirements for successful application. By using a methodology that combines the strengths of both approaches, it is possible to overcome the individual weaknesses of each one. The volume of calculations required by this technique prohibits manual data […]

Read more »

Steps in Constructing a p-Chart

Published:Steps in Constructing a p-Chart: p Charts can be used when the subgroups are not of equal size. This guide shows you the steps involved in constructing a p Chart.

Read more »

Control Chart Wizard – p-Chart

Published:Control Chart Wizard – p-Chart: Control charts dealing with the proportion or fraction of defective product are called p charts (for proportion). There is a difference between a defect and defective, as there is between a nonconformity and nonconforming unit. The p-chart control chart is used with discrete/attribute defective data when the sample size is greater than 50. The sample size may vary.

Read more »

Steps in Constructing an np-Chart

Published:Steps in Constructing an np-Chart: The np Chart can be used for the special case when the subgroups are of equal size. Then it is not necessary to convert nonconforming counts into the proportions phat(i). Rather, one can directly plot the counts x(i) versus the subgroup number i.

Read more »

Control Chart Wizard – np-Chart

Published:Control Chart Wizard – np-Chart: The np control chart are used to monitor the number of nonconforming units in samples of inspected units. A nonconforming unit is a product which fails to meet at least one specified requirement. There is a difference between a defect and defective, as there is between a nonconformity and nonconforming unit. The np-chart control chart is used with discrete/attribute defective data when the sample size is greater than 50. The sample size must be constant; this control chart is only valid if data is collected in same-size subgroups.

Read more »

Control Chart Wizard – Discrete Defective Data

Published:Control Chart Wizard – Discrete Defective Data: How large is your discrete/attribute defective data sample size?

Read more »

Control Chart Wizard – Discrete Defective Data

Published:Control Chart Wizard – Discrete Defective Data: How large is your discrete/attribute defective data sample size?

Read more »

Steps in Constructing a u-Chart

Published:Steps in Constructing a u-Chart: The u Chart is used when it is not possible to have an inspection unit of a fixed size (e.g., 12 defects counted in one square foot), rather the number of nonconformities is per inspection unit where the inspection unit may not be exactly one square foot…it may be an intact panel or other object, different in sizethan exactly one square foot. When it is converted into a ratio per square foot, or some other measure, it may be controlled with a u chart. Notice that the number no longer has to be integer as with the c chart.

Read more »

Control Chart Wizard – u-Chart

Published:Control Chart Wizard – u-Chart: Control charts dealing with the number of defects or nonconformities over time are called u charts. There is a difference between a defect and defective, as there is between a nonconformity and nonconforming unit. The u-chart control chart is used with discrete/attribute defect data when the sample size varies.

Read more »

Steps in Constructing a c-Chart

Published:Steps in Constructing a c-Chart: The c Chart measures the number of nonconformities per “unit” and is denoted by c. This “unit” is commonly referred to as an inspection unit and may be “per day” or “per square foot” of some other predetermined sensible rate.

Read more »