If your organization uses a single-piece flow cell manufacturing process, then Chaku Chaku might be the right setup for you. In this article, we’ll discuss how Chaku Chaku is performed in a manufacturing process, its benefits, importance, and best practices.

Overview: What is Chaku Chaku?

The traditional manufacturing approach is to group similar machines performing similar operations in separate parts of the facility. These machines turn out hundreds of parts in batches and then are transported to another area, or go into WIP (work in progress inventory). Batches of parts and assembled components move step by step through the manufacturing process.

The foundation of Chaku Chaku is one-piece flow and lean work cells. Let’s look a little closer at each.

One-piece flow is a system in which products (or parts) are moved through a manufacturing operation in a continuous flow, one piece at a time. There is no WIP. One-piece flow is an integral part of the Toyota Production System. A batch process is the opposite of one-piece flow, where a batch of parts are worked on, and then passed onto the next workstation.

The following conditions should be met for a one-piece flow system:

- Output should be consistently defect-free.

- Process times should have minimal variation.

- Equipment should have a very high level of reliability.

- Production should be flexible to respond to changes in customer demand.

With Chaku Chaku, all of the machines needed to make a similar product are located together in a work cell. Machine unloading can either be automatic or manual. The operator will manually load the machine, which is why Chaku Chaku is Japanese for load load. The operator only loads the machine and then moves on to load the next machine.

It is usually more complicated to manually load a machine into a well-defined position, thus requiring a human task. On the other hand, it is much easier to simply eject the part from the machine. This automatic unloading of the machine is referred to in Japanese as Hanedashi (to jump; to leap; to spring up). It is also possible to have a manual unloading of the part, although it might no longer be a Chaku Chaku line. The automatic unloading is often faster than the time the worker needs for manual unloading. Additionally, the operator may have to unload a part while awkwardly holding the next part to be loaded in their other hand.

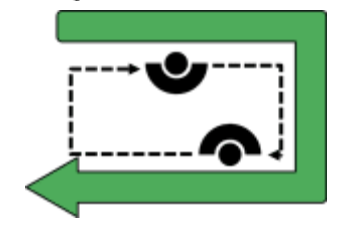

A work cell includes everything needed to make a part, or a group of similar parts. The needed machines are arranged in the sequence they are needed to make the part, usually in a U shape cell. This results in a smooth flow of materials into one leg of the U and a smooth flow of parts out of the other leg of the U.

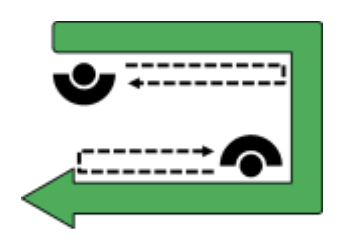

The number of operators in a Chaku Chaku line can be flexible. Here are some of the different approaches if you use more than one operator.

Bucket brigade

Here, the operators move forward until they meet the next operator and then return backward until they meet the preceding operator.

Baton touch

Another approach is when each operator is responsible for a section of the line and hands over the work to the next operator. This is a common method.

Rabbit chase

Finally, all operators do the same loop behind each other.

3 benefits of Chaku Chaku

If Chaku Chaku is appropriate for your organization’s manufacturing processes, you will incur a number of benefits using one-piece flow and work cells.

1. Reduced WIP

Using a one-piece flow approach rather than batches will reduce your WIP.

2. Reduced movement of parts

Completing all the necessary work within a limited cell configuration will reduce the movement of parts and components.

3. Greater flexibility

A single operator can run multiple processes, providing greater flexibility.

Why is Chaku Chaku important to understand?

It is important to understand when to use Chaku Chaku since it is not applicable to all manufacturing processes.

Equipment reliability

Since there is a reduced number of machines in a cell, your equipment must perform at a high level of reliability. If a piece of equipment goes down, it may shut down the entire cell.

Not good for a job shop

Chaku Chaku is based upon the premise of one-piece flow and a somewhat consistent and repetitive process with little variation in processing times. A job shop will have too much variation to be a good candidate for Chaku Chaku.

Defect free

A continuous flow of product requires a high level of quality in the output, otherwise the process will not flow smoothly and the value of Chaku Chaku will be greatly diminished.

An industry example of using Chaku Chaku

Wing Manufacturing is in the business of producing components for the aircraft industry. In the past, they located their machines in separate areas of the factory, with each machine using a single operator. They turned out hundreds of parts in batches, which were loaded onto carts for moving to another area for further processing or sat on the carts waiting until either they were needed, or the whole batch was completed.

The equipment was large, complex, and expensive. By incorporating the fundamental principles of Chaku Chaku and designing equipment specifically for the type and size of the parts being manufactured, Wing Manufacturing was able to free up over 2,000 square feet of factory space. This allowed them to add another line to handle increased customer demand.

The machines in the new Chaku Chaku line were designed as a U-shaped flow line. The machines ejected the parts automatically, and everything was sequenced so the operators didn’t spend time unloading or waiting. By the time the operator got to the end of the line, the machine cycle of the first machine was completed, and the whole process started over again.

The line was only assigned resources (equipment and labor) required for the specific activities to be performed that day. Included in the line were appropriate inspection tools to ensure no quality problems were passed on to the next operation.

Because each line was responsible for turning out a completed product, it was easier to keep track of how many parts were being produced and to adhere to the schedule. Each machine received a certain amount of raw material each day, so they knew exactly how much work they had to produce. With the old setup, they were never sure how much would get produced because one part might be held up in another area, preventing it from moving forward.

There was less WIP in the process and less movement of parts, thereby reducing congestion in the workplace and less damage resulting from moving parts around.

3 best practices when thinking about Chaku Chaku

Here are a few tips for getting the most value out of using Chaku Chaku for your manufacturing process.

1. Use automatic unloading

Where feasible, use manual loading and automatic unloading to optimize the Chaku Chaku strategy.

2. Machine design

Using specially designed and sized machines for your parts will make the process more efficient and free up floor space.

3. Number of operators

Balance the workload, and don’t overstaff the Chaku Chaku line — otherwise, the line efficiency will go down.

Frequently Asked Questions (FAQ) about Chaku Chaku

1. What does Chaku Chaku mean?

It is a Japanese word meaning load load and refers to a manufacturing system where the task of the operator is to load consecutive pieces of equipment in a one-piece flow, work cell environment.

2. What is Hanedashi?

It refers to the automatic ejection or unloading of parts from a machine used in conjunction with Chaku Chaku.

3. What are the most common configurations when using multiple operators on a Chaku Chaku line?

Bucket Brigade, Baton Touch, and Rabbit Chase are the three most common configurations.

Chaku Chaku summary

Chaku Chaku, meaning load load in Japanese, is a production system based on the use of a one-piece flow of product and work cells. Using a cell of specialized equipment sequenced to the order of production, the operator walks the line loading new parts while completed parts are automatically ejected or unloaded.