The quality function deployment methodology is a 4-phase process of cascading matrices that takes the product development cycle from gathering Voice of the Customer (VOC) to design requirements, then all the way down to requirements for process and product quality control.

This article will present the four phases of QFD, the benefits of QFD, some best practices for using it.

Overview: What is QFD?

QFD was developed in Japan by Yoji Akao in about 1966 while working for Mitsubishi. Toyota and other auto manufacturers started using the approach later on.

Akao described QFD as a “method to transform qualitative user demands into quantitative parameters, to deploy the functions forming quality, and to deploy methods for achieving the design quality…”

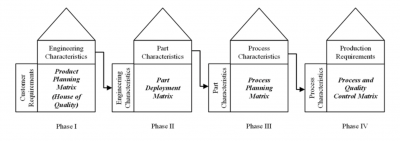

The QFD four cascading matrices, sometimes referred to as Houses, are:

- Product Planning Matrix: The first phase starts with your collection of the VOC and translates your customer wants and needs into specific product and service requirements and specifications. It also involves a competitive analysis to evaluate how well your competitors fulfill your customer wants and needs. The initial design concept is based on the particular product and service performance requirements and specifications. This first House is referred to as the House of Quality and is the foundation of your QFD process.

- Part Deployment Matrix: During this phase, the assemblies, systems, sub-systems, and components that have the most impact on meeting your product and service design requirements are identified. The critical product and service characteristics cascade down and are translated into critical parts and assembly characteristics or specifications as well as steps of a service process. These requirements or specifications are then defined for each relevant functional area.

- Product and Service Planning Matrix: During this phase, the manufacturing and assembly processes are designed based on your product and component specifications. So far, you have gone from customer requirements to product requirements to process requirements.

- Process and Quality Control Matrix: Before a full product launch, you may want to run a pilot. Now that you have identified the product and process characteristics, you’ll want to be sure you have developed and implemented adequate process and product quality controls. These can be confirmed during your pilot. Full production should not begin until the process is shown to be in control and exhibiting common cause variation — and that process capability studies have been completed.

Here is a visual of the four phases. The “what” of one phase leads into the “how” of the next phase.

Image source: www.researchgate.net.

3 benefits of QFD

Although there is a good bit of work in developing and building your QFD, the benefits of having all of the elements of your design process in a series of easy-to-read diagrams is well worth the work and effort to develop it.

1. Organized way to gather input from your customers

The QFD phases, or Houses, are structured and the elements linked. You can’t complete the QFD without completing each previous House.

2. Focused development

By using QFD, you are forced to focus your development efforts on your customer’s needs and specific requirements. This provides discipline to your development process.

3. Fewer development oversights

By adhering to the discipline and structure of the QFD process, you will reduce your chance of missing or overlooking something during your development process.

Why is QFD important to understand?

The different phases of QFD are linked and build on each other. Understanding this linkage and the cascading of the how of one phase feeds into the what of the next phase is the secret of being able to successfully use QFD.

Customer-driven, not technology-driven

The power of QFD is that it is your customers’ needs driving the technology, and not the technology driving your customers’ needs.

Linkage

QFD is a series of linked and cascading matrices that build upon the previous phase.

Importance of teamwork

QFD requires teamwork across many organizational functions.

Marketing and sales first identify key customer needs and wants. This information provides the input to engineering, who will produce the product’s technical specs. Manufacturing has to design the process to actually produce the product. Quality now gets involved to be sure that the product meets all specs and expectations. Marketing reengages to communicate the new product’s features to your customer.

All of these functions must work together in a collaborative manner to accomplish the goal of providing a great product for your customer.

An industry example of QFD

A large financial institution wanted to create a new model for a brick and mortar banking center. Their Master Black Belt, Gil, suggested the use of QFD as a way to design this new approach to banking.

They gathered extensive voice of the customer (VOC) to determine the requirements of how people want to bank at a banking center. Using the customer feedback they built their House of Quality (HOQ). This consisted of determining banking process attributes, correlating them and setting targets for each based on customer expectations. They also compared how their competitors were doing with respect to the same requirements.

Cascading down from the HOQ, they engaged their construction, facilities and IT departments to help with QFD phases 3 and 4. The purpose was to develop specifics around the banking center design and processes along with the construction process. Once this was done, they brought in the quality control group to help set the specifics of how they would assure all processes worked as they should and all customer requirements were met.

Their new model was successful and they picked up significant market share from their more traditional banking competitors.

3 best practices when thinking about QFD

While the intent of QFD is to shorten the development process, it still takes time to complete the four phases. By following some best practices, you may be able to be more efficient in doing that.

1. Get the House of Quality done right

The House of Quality is your first phase and is the foundation of the other QFD phases. Without a clear definition of the customer’s needs, the final outcome is likely to fall short of satisfying your customer.

2. Let the data speak

While there are some subjective components of QFD, try to support your decisions with data. You don’t want to make critical decisions just based on intuition and gut feelings.

3. Stretch is good, but shooting for the moon may not be

The goal of QFD is to meet your customer’s requirements and needs. It’s fine to develop a stretch product or process, but trying to hit the ball out of the park and create the world’s next best thing may not be realistic or cost-effective.

Frequently Asked Questions (FAQ) about QFD

How is House of Quality different from QFD?

QFD is a four-phase process that takes your Voice of the Customer and translates that to customer requirements, then to specific part or component requirements, then to specific process requirements, and finally to quality control requirements.

House of Quality is the first phase of taking VOC and translating it to customer requirements.

Can QFD work in the service industry?

Yes. Phase one of QFD translates your VOC to the specific design requirements of the service you plan to offer. Phases two and three develop specific components of your service and specific process requirements to deliver your service. Phase four will develop your quality control processes to be sure you’re delivering your service with high quality.

Will QFD replace my current product development methodology?

If you already have a functioning development process, QFD can be used to help support and enhance your current process, not replace it.

Let’s circle back and summarize QFD

QFD is a systemic, structured, and proven methodology for embedding your Voice of the Customer feedback into both your initial design requirements and final production and quality control processes.

Every business, organization, and industry has customers. Meeting your customers’ needs is critical to success. Implementing QFD can enable you to drive the voice of your customers throughout your organizational processes to increase their satisfaction and delight.