As a recently promoted Vice President, Chuck needed to quickly understand what all his people were doing.

Chuck, a longtime employee of a major utility company, had been recently promoted to Vice President to take over the leadership of a wide range of different functions than what he had been managing. As a result of his new position, Chuck was put in charge of Customer Services, with oversight of the meter to cash process. This process encompassed about $7 billion in cash flow.

Chuck hired a team of two consultants to help him map, document, and improve the process. An initial review of the organization indicated there were documentation, and efficiency opportunities across the Customer Services organization. The Remittance process department was prioritized first, as there were immediate process documentation opportunities and the process had a high impact on the organization.

The Director of the Remittance process, Mitch, was a thirty-year veteran of the company. As an initial step, the consultants had a Zoom meeting with Mitch to explain what they would be doing and how they might help Mitch improve the process. It was not a surprise when Mitch reacted in a negative and defensive fashion, and explained his process was working perfectly and there were no problems to be improved. Fortunately, Chuck had made it clear that the consultants were there to help him, and he needed to be open and cooperative.

Additional meetings were held with the managers of the six subprocesses which comprised the Remittance process. The tasks of Remittance included:

- bill creation, printing, and delivery/mailing

- payment, deposit of funds and reconciliation

- financial reports and compliance

Initial discussions were also held with the remaining Directors of Chuck’s organization, since their processes were all linked with the Remittance process. A presentation was made to all the staff to be fully transparent about what the consultants were going to do and why.

Mitch was resolved to make the best of the situation, so he set up an aggressive schedule for the consultants to meet and work with his managers.

The managers were excited about the opportunity to discuss their processes and suggest ways to improve them. They were open and direct about their process and some of their challenges. Two hour Zoom meetings were set up to meet with Mitch, each manager, and their staff. Each manager met with the consultants twice a week for a period of 10 weeks. Additional meetings were held with Chuck’s other directors and managers to help everyone understand the interrelationships of the various processes and how they impact each other.

The Road to Improvement, developed by the two consultants, was used as the format for finding out how the processes were performing. Miro, the online visual collaboration platform was used for the bulk of the work. Microsoft Visio was used for the final and more complex process mapping. The ten steps of the Road to Improvement, along with examples are shown below:

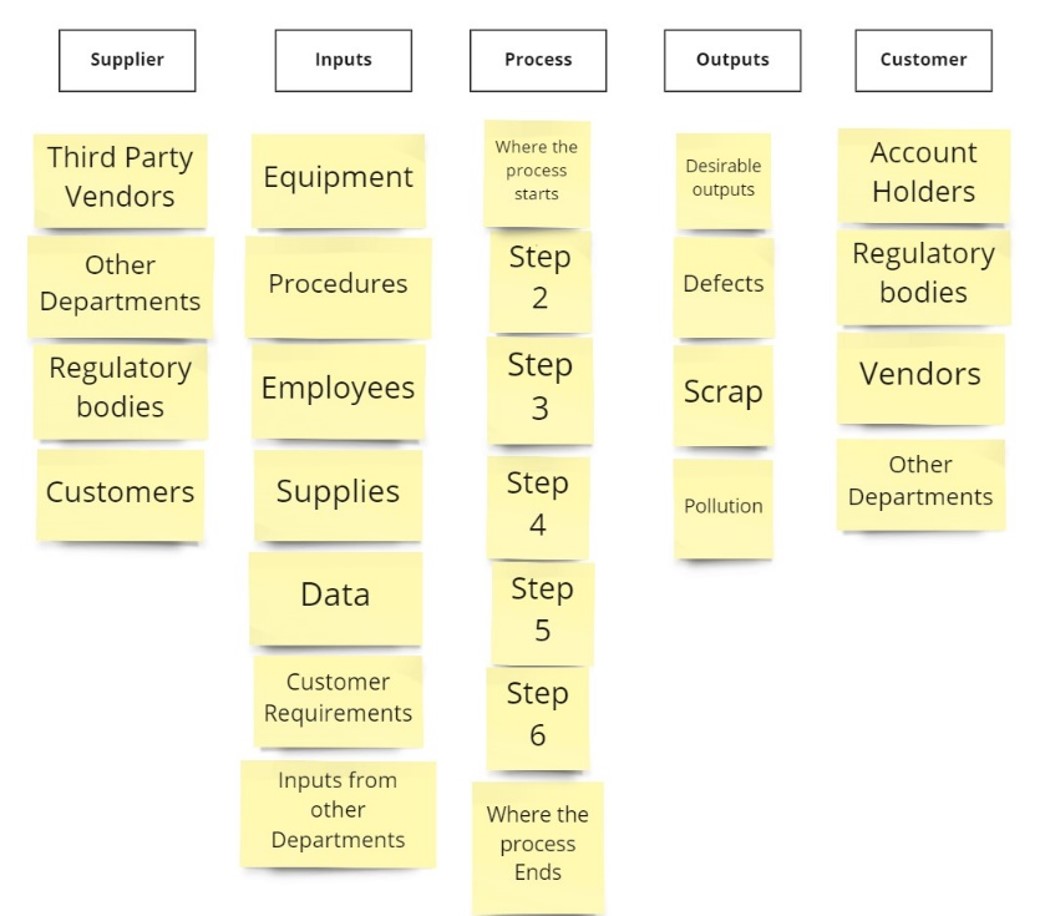

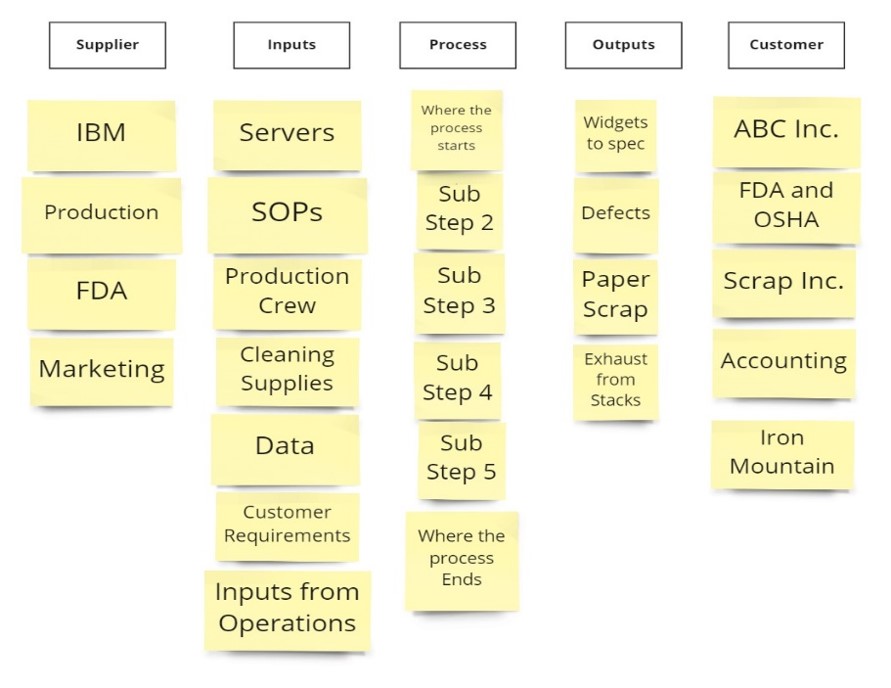

1. Create a Level 1 SIPOC Map (Supplier-Input-Process-Output-Customer) of the high-level (level 1) organizational process. Miro allowed for the use of “post it notes” just like you would use for an in-person session.

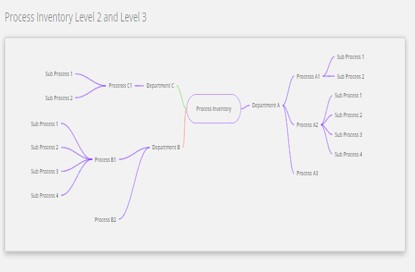

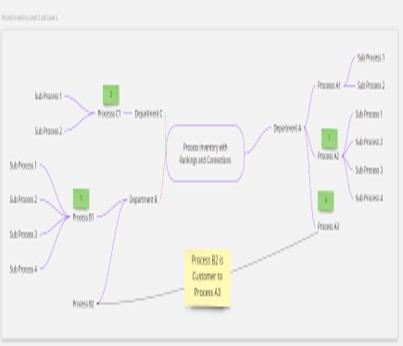

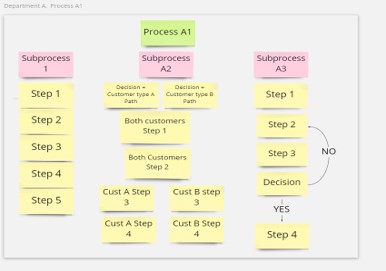

2. Develop a process inventory to identify all key processes at the next level and document interrelationships between those processes. The mind map feature in the Miro application was a perfect tool for creating the process inventory.

3. Identify the most critical work processes using the process inventory – this provides a strategy for digging deeper into the most important work.

4. Create a Level 2 SIPOC for each of the critical processes. Drill down to the next few levels, as appropriate, and create the level 2 SIPOCs of the most critical level 2 processes.

5. Create the level 2 process flowchart draft using the SIPOC process as a starting point. The teams drilled down to the next few levels, as appropriate, and created the level 2 SIPOCs of the most critical level 2 processes. Starting with the process steps in the level 2 SIPOC, the team captured the process flow and steps. This resulted in a draft version of a Value Stream Map. This informal approach of following the process flow was appreciated by team members who had not done flowcharting before.

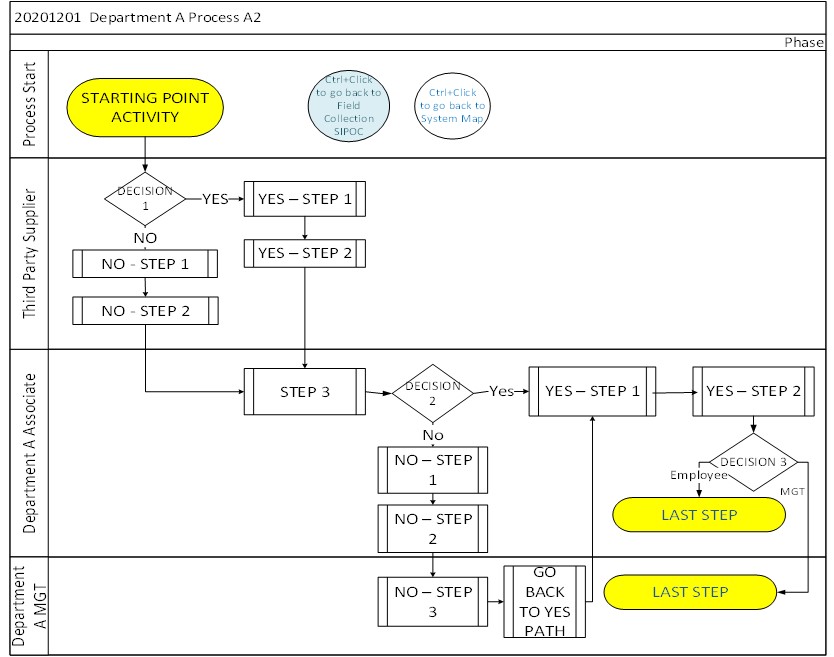

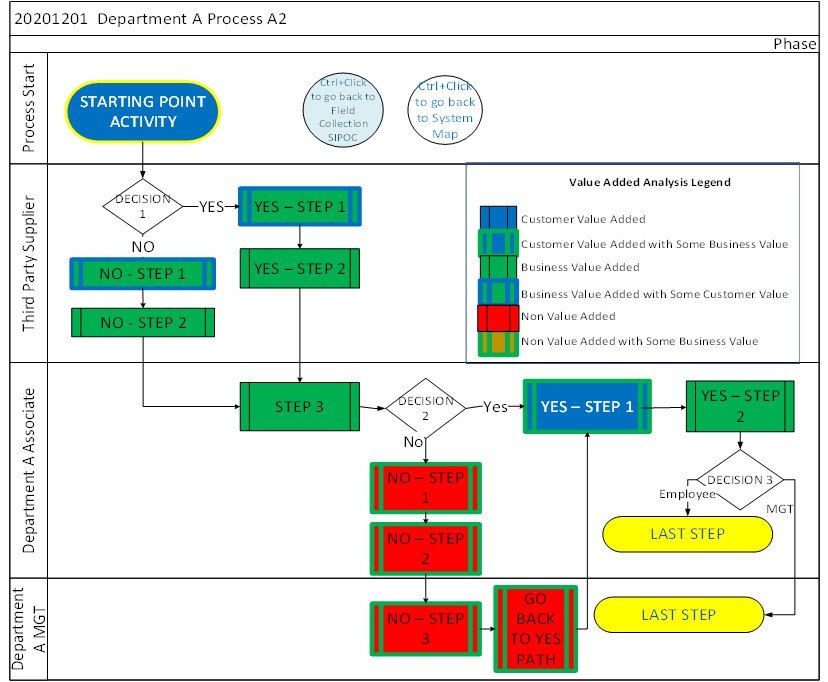

6. Convert the process flow map to a Visio Swimlane diagram for more clarity and detail (the Visio mapping happened off-line by the consultants and then was confirmed with the team).

7. Do a Value Analysis using the Visio diagram as the foundation. Distinguish which activities are Customer Value-Added (CVA), Business Value-Added (BVA) and Non-Value-Added (NVA). Identify any pain points that exist in each process step. Using the Visio diagram as the foundation helped distinguish which activities were CVA, BVA, and NVA. The team then identified any pain points that existed in each process step.

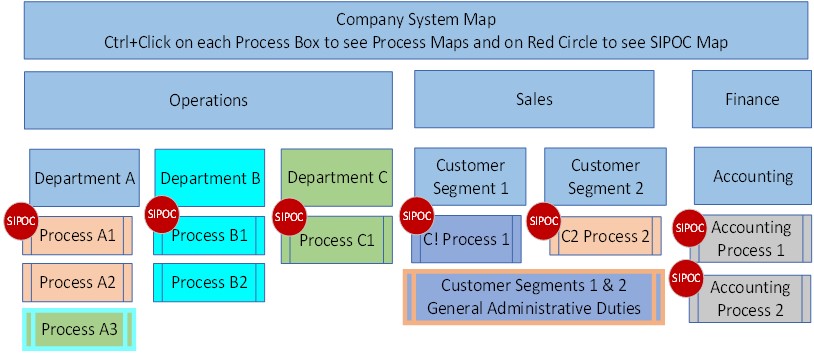

8. Create a dynamically linked Visio System Map linking all the critical processes and the relationships between those processes. This took a complex system of process maps, organized it within and between departments, and put it all at the team’s fingertips in an easy to navigate format. The system map may be seen as a living document of the system of processes that will need to be continually updated.

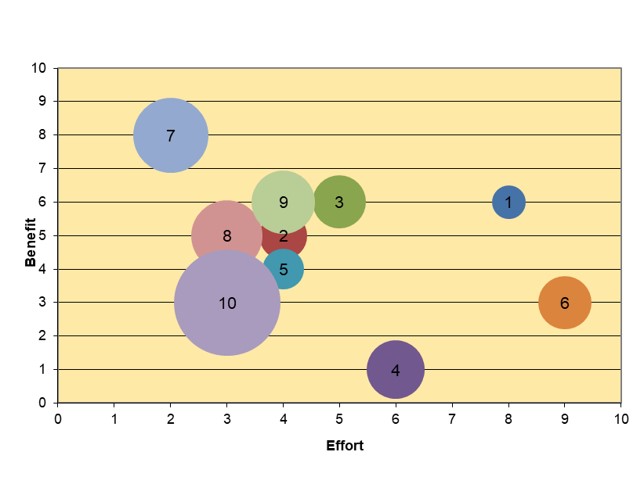

9. Identify the best opportunities for improvement from the Value Analysis. A simple Benefit/Effort Matrix is a useful tool for this activity. The sweet spot is high benefit and low effort projects. However, high benefit, high effort projects should not be ignored. They can be real game changers. The team was able to identify some short-term improvements that could be implemented quickly to convince senior leadership the value of using the Road to Improvement.

10. Form Improvement Teams of varying complexity, depending on the desired improvement. The team used data and the basic tools of improvement to put improvements in place. Kaizen events were used, along with full blown DMAIC or DMADVI/DMEDI projects, to develop improvement recommendations and implement complex process improvement.

Mitch went from being negative to being an advocate and change agent.

After a month of focused meetings, Mitch started to change his attitude once he saw the enthusiasm of his managers for the process mapping and analysis they were doing. He also realized that there were many things going on in the various processes which he was not aware of. By the end of the process, he had become an advocate for what his managers were doing and shared his enthusiasm with Chuck’s other directors.

Given the success of the consultants with the Remittance process, Chuck’s other directors were encouraged to replicate what Mitch had done. With several of Chuck’s staff retiring in a few years, including Mitch, Chuck was very satisfied that his processes were now documented with process maps, process inventories and detailed flow charts. Additionally, the elimination of non-value work and improvement of the process generated over $5MM in annual savings because of reduced errors, rework, and excess labor costs.

5 best practices if you decide to take the Road to Improvement

- Virtual – It is important to note that the steps of the Road to Improvement can be done in virtual team meetings using web-based teleconferencing platforms and collaboration applications. Virtual meetings also mean no travel (and its costs) and a safe COVID-free working environment for your team and your facilitators.

- Executed in digestible chunks – Prior to the Pandemic and the subsequent move to remote work, the Road to Improvement required a team workshop lasting approximately three full days onsite. According to the consultants, using more frequent meetings (twice a week up to daily) and shorter time frames (2 hours) is an optimal approach to progressing through the Roadmap to Improvement while still getting daily work done. Also, more than two hours and the intensity of the sessions tends to lead to intellectual fatigue and diminishing returns.

- Iterative – the learnings build throughout – The two-hour blocks of work spread out over a few weeks allows the participants to think about, digest, internalize and review their work output often resulting in greater enthusiasm about the process and the opportunity to go back and observe the application of what they did in the actual workplace. This creates a greater insight for the participant. The consultants found that when you start with a review of the previous work in the next session, there is often constructive revision because the participant went back and viewed their process in a different light.

- Facilitated by experts – The facilitation of the Road to Improvement is critical to success. Objective interrogation of the process by external experts keeps the team from falling into the traps of thinking that “we have always done it that way” or a defensive posture because somebody may be “calling their baby ugly”. Facilitators will also ensure your teams make the most out of every session and never drive into a ditch along the road or go down a rabbit hole. They will take as much of the work as possible offline while your team spends their time on what matters most – using their expertise to build the substance of the maps that will document your system and identify fertile areas for improvement. This means your team need not become experts in Miro, flow charting or Visio swim lane process mapping – unless they want to!

- Fun – People warm up to these meetings quickly. The Facilitators find humor in the process, making it an enjoyable experience. The teams really enjoy talking about their passion – the work they do. They are excited to make an impact by improving things that keep them from doing their best work every day. Once the Facilitators build an environment of trust and respect with the team then change management is easier because the improvements come from people who DESIGN and WANT the change. You must convey the idea that you are not there to criticize, intimidate or judge their work efforts but to help them bring out the best in them and help make their processes and jobs the best they can be. And to top it off, the feedback has been that the team members learn a lot about their own processes and appreciate that the deliverables will help them to speak clearly and concisely to other departments about how to best collaborate to get top results.