In this article, we present a distinct account of discrete data. By the end of our time together, you will be able to employ discrete data with certainty.

Overview: What is discrete data?

There are two categories of data:

- Continuous data is data that can be measured on an infinite scale, It can take any value between two numbers, no matter how small. The measure can be virtually any value on the scale. Measures of time, height, temperature, and thickness are all examples of continuous data.

- Discrete data is data such as occurrences, proportions, or characteristics (for example, pass or fail) and is counted (for example, the number or proportion of people waiting in a queue, or the number of defective items in a sample). Discrete data is counted in non-negative integers (1, 2, 3, etc.).

Take color, for example. Your product might come in five different colors or categories. You can count the occurrences of each color (category) in your data sample. Count is indivisible — it doesn’t make sense to have 1.5 blue products.

1 benefit and 2 drawbacks of discrete data

There are a few important things to know about discrete data.

1. It provides information about the count of items in each process measure or outcome category

Discrete data can be summarized with a frequency table that shows the count of each category in the data sample.

2. It requires more data when used in graphic analysis and statistical tests

Discrete data requires large sample sizes for graphs and statistical analysis. To collect a large enough sample can be expensive in terms of time, money, and staff. On the other hand, it can be easier to collect than continuous data if you have clear definitions of the data categories.

Discrete data is less efficient than continuous data. It can tell you whether a product weight is defective, but it can’t tell you how much the product actually weighs.

3. It’s only as good as the measurement system that generates it

I call this a drawback, but measurement system analysis is really the price of entry for discrete data analysis. Discrete data can be taken by both humans and machines.

It is important to make sure that the people sorting the data into categories (sometimes called inspectors) agree on the category for a given product.

Machines that provide count data must also be studied to determine that their output is trustworthy. It’s your responsibility as a discrete data analyst to study and correct any issues with your inspectors or measurement equipment prior to analyzing the data it provides.

RELATED: DISCRETE VS. CONTINUOUS DATA

Why is discrete data important to understand?

You must determine if the data generated by processes measures and/or process outputs is discrete in nature in order to do the following two things.

To choose the right statistics to describe the sample

Discrete data may be summarized by counting occurrences of each category. You might also like to calculate the proportion (or percentage) of occurrences of a category in a sample.

To choose the right analysis tool

The tool you want to use in graphic or statistical analysis will specifically require either discrete data or continuous data.

If, for example, you accidentally use discrete data for a tool that requires continuous data, you can draw incorrect conclusions from the tool’s output. If you act on those incorrect conclusions, you may not get the results that you wanted, wasting both time and money.

An industry example of discrete data

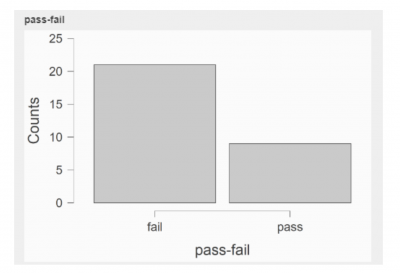

Discrete data from a curing oven test (pass/fail the test) was collected to check if the curing oven could be used for a new product. The engineer wants to check how many times the oven test failed or passed. The engineer needs to:

- Verify the curing oven test pass and fail can be correctly identified with a Gage R&R Study. Assuming the gage passed…

- Make 30 curing oven tests over the course of one day of curing the new product. Classify each one as pass (in temperature range for the new product) or fail.

- Plot the data in a bar chart.

The bar chart of the 30 discrete data points has 20 fails and 10 passes.

What can this discrete pass/fail data tell us about the curing process?

- The discrete data tells nothing about the center or spread of the data, only how many readings passed the curing oven test and how many failed.

- There are twice as many curing oven fails as there are passes. That is not good news.

- The discrete data can tell us how many more failed curing oven tests there are than passed tests. However, the discrete data cannot tell us if the curing oven fails are too cool or too hot. For that, we need the temperature continuous data.

Based on what they learned from the discrete data bar chart, the engineer decided to take action and study the curing oven components.

A mechanical check of the oven showed a thermostat was not functioning. It was replaced. The number of tests that fail is now 0, and the curing oven is good to use with the new product.

3 best practices when thinking about discrete data

If you want to analyze data like an expert, keep these three things in mind.

1. Use Excel or a statistical and graphic computer program to analyze your discrete data

The days of plotting discrete data in frequency tables and calculating discrete data statistics by hand are long past. Find an analysis program that suits your needs and your budget.

Your company may allow you to download Minitab, JMP, or Excel. If not, you can search for free, open-source statistics software on the web. “R” software, for example, is free and used by many universities.

2. Assess your data for stability before you start analysis of discrete data

Before you use discrete data to represent your process measure or outcome, it’s important you know whether your process is in statistical control.

If your discrete data plot is not stable, you should do some process improvement work to move it toward stability.

Analysis of discrete data that is unstable only applies to that sample of discrete data. If the process is in statistical control, the analysis of the discrete data may also be applicable to the process samples from the near future.

3. Plot the data, plot the data, plot the data

A picture is worth a thousand words. Statistics support the graphs — not the other way around. Always begin discrete data analysis with frequency tables, a bar chart, and a control chart.

Frequently Asked Questions (FAQ) about discrete data

What graphs are good to use with discrete data?

There are many — bar charts, pareto diagrams, and control charts are some of the most popular.

Can discrete data ever be treated as though it is continuous data?

Sometimes. If the discrete data is binary in nature (for example, pass or fail), then no, you should only count the occurrences of the two categories of data.

However, if the discrete data is count data that is ordered (for example, 1 is smaller than 2 and both are smaller than 3), and you are seeing 10 or more possible values of counts (rating scales that go from 1-10, for example), then you may safely use continuous statistics like the average and plot the data in with a histogram.

If you think you have data such as this, check with your data analysis expert before you begin analysis.

Some final thoughts on discrete data

Discrete data are “category” variables, (e.g. color, defect type, or pass/fall) or ordered rating scales (like Likert scales for strength of agreement). Analysis of discrete data can tell you the occurrence or proportion of categories in a sample.

While discrete data will not give you as much information about your sample as continuous data can, it is still useful and informative of your process measure or outcome.