As long as humans are part of your process, there is a chance they will make mistakes and errors. Let’s see how the use of EMEA may help prevent or mitigate the impact or effect of those errors on your process.

Overview: What is Error Mode Effects Analysis (EMEA)?

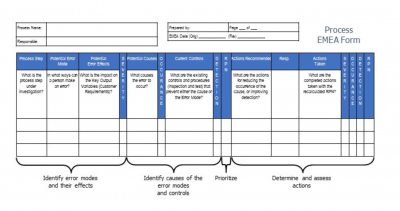

EMEA is an extension of the Failure Mode Effects Analysis (FMEA). FMEA is a common tool for mitigating risk in a process. It can be done in each of the Six Sigma DMAIC stages. While FMEA identifies the potential ways a process can fail, the EMEA focuses on the potential errors due to human or people failures. As such, it is more applicable to transactional processes rather than manufacturing. Here are the steps for doing an EMEA:

- For each process step, determine the ways in which a human error can occur (error mode).

- For each error mode, determine the potential impact or effects and select a severity level for each effect. You can use a scale of 1-5, 1-10 or a simpler 1, 3, 9 scale. The 1-5 scale makes it easier for the teams to decide on scores. The 1-10 scale allows for better precision in estimates and a wide variation in scores (most common). The 1-3-9 separates the scores yet keeps it simple

- Identify potential causes of each error mode and select an occurrence level for each cause.

- List current controls in place which would prevent each cause and select a detection level for each.

- Calculate the Risk Priority Number (RPN) by multiplying the severity level times the occurrence level times the detection level.

- Develop recommended actions, assign responsibility for the actions, and then make the changes. Give priority to the high RPNs. Regardless of the RPN, you MUST look at severities rated a 10.

- After the changes have been made, recalculate the RPNs.

Here is the typical format for an EMEA:

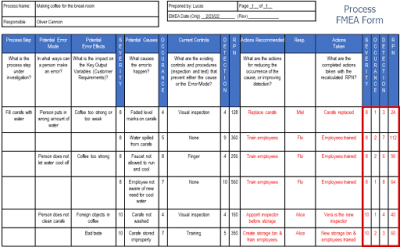

An Industry Example of EMEA

The Human Resources Manager was interested in trying to do a simple EMEA as an example for his team. He chose to use the coffee making process in the company break room as his example since there were multiple complaints about how the coffee tasted. He put together a small team of employees who created the following EMEA:

Frequently Asked Questions (FAQ) about EMEA

1. What is EMEA used for?

It is a tool used for risk mitigation in a process. It analyzes a process for potential human errors, the impact and severity of those errors, the possibility of occurrence and what controls are currently in place to detect the errors.,

2. What is the difference between EMEA and FMEA?

EMEA focuses on the possibility of human errors in the process while the FMEA looks at the process from a broader context of process steps, inputs, products or components.

3. What is the Risk Priority Number (RPN), and how do I calculate it?

The RPN is the multiplication of the error severity, occurrence and detection. It is an overall measure of the impact of an error on the process. You will use the RPN to help prioritize process changes and error mitigation actions.