Reducing changeover time for equipment is a fundamental principle of Lean Manufacturing. You can define setup time as the time from the last good unit of a run to the first good unit of the next run. Assuming you have sufficient demand, the faster you can change over your equipment, the more total time you will have to produce your products.

Overview: What is SMED?

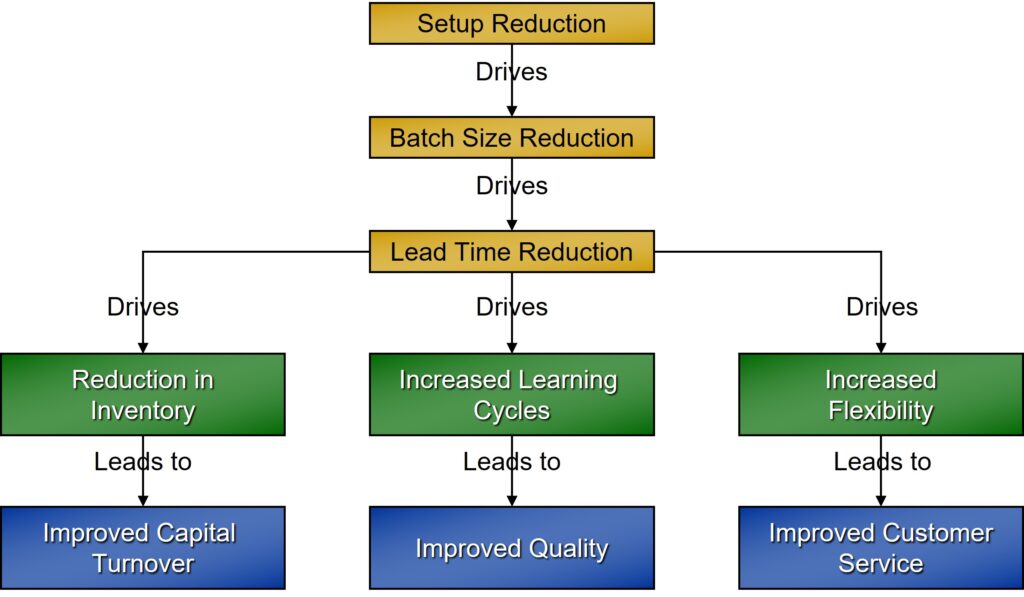

SMED was developed by Shigeo Shingo, a Japanese industrial engineer who had worked at Toyota. The Single Minute stands for a single digit minute, that is, less than ten minutes. Some of the benefits of SMED are:

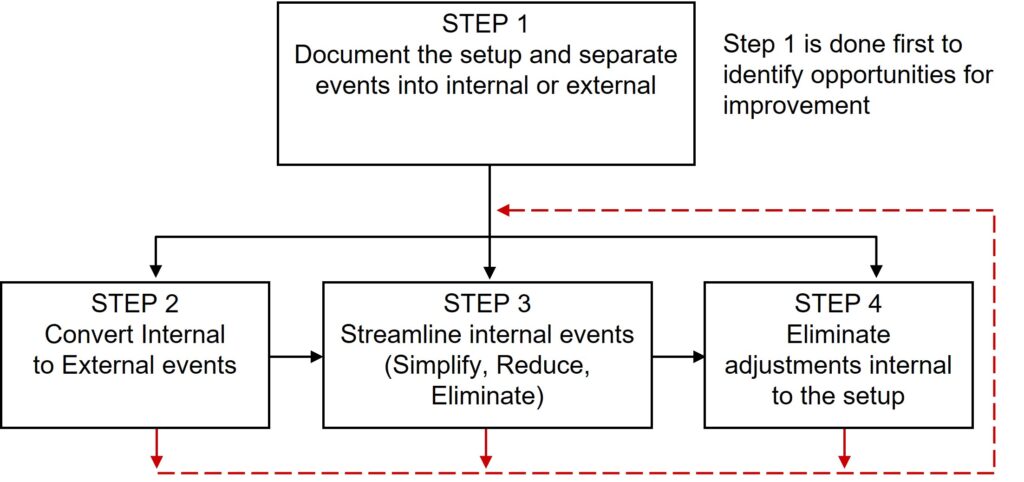

SMED is a four-step process. Here the steps:

Step 1:

Document all the setup activities and then separate them into internal and external elements where an:

- Internal element is an activity that must be performed while the equipment is down

- External element is an activity that could be performed in parallel while the equipment is running

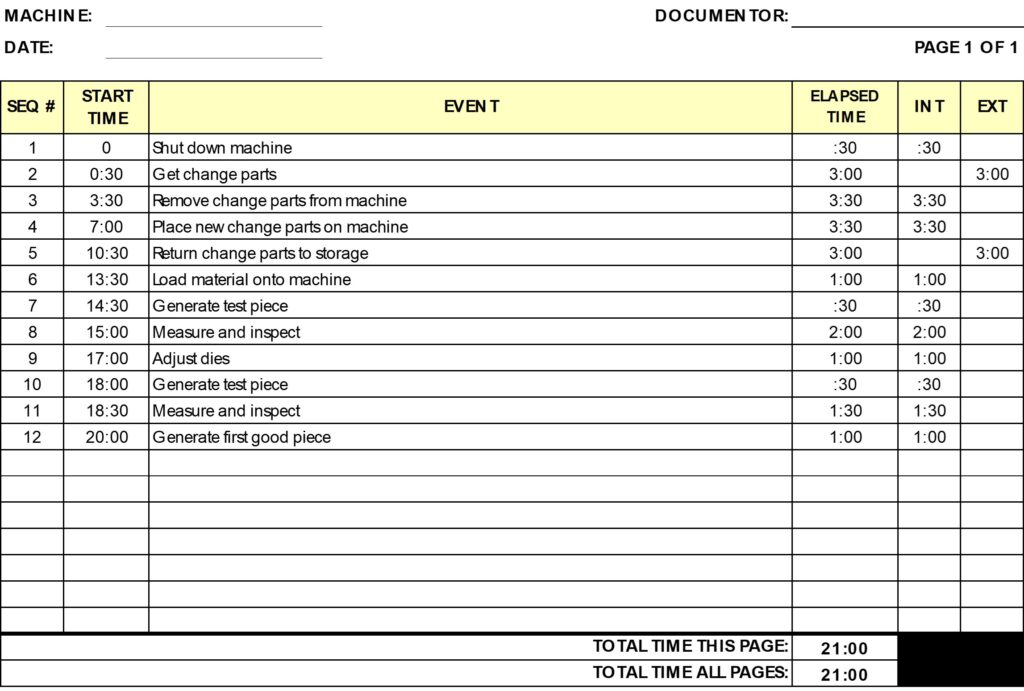

You may use a form like the one below:

Step 2:

Convert Internal to External elements

- Convert any internal elements to external elements using focused, engineered methods

- Re-examine internal elements from Step 1 and verify that they are actually internal

Step 3:

Streamline Internal elements by:

- Simplifying movement

- Reducing movement

- Eliminating movement

- Reduce/eliminate need for hand tools

- Reduce/eliminate nuts and bolts, hex nuts, etc.

- Replace with quick fastening/releasing devices such as below:

Step 4:

Eliminate adjustments

- The elimination of adjustments and trial runs by turning intuition and guessing into fact and settings

- Elimination means elimination – not reduction in the time required to perform adjustments

An industry example of SMED

A Six Sigma Black Belt was doing an analysis of changeover time for a pharmaceutical tablet manufacturing line. The bottleneck was the cleaning step once the line shut down. This took over an hour to complete since everything had to be hand wiped to be sure product contamination between runs did not occur. Obviously, the cleaning couldn’t be done while the machine was still running.

A team was formed to come up with suggestions to reduce changeover time. Rather than focusing on the cleaning process itself, the team approached the problem from the perspective of an internal or external element. Currently, the cleaning was defined as an internal event since it couldn’t be done while the machine was running.

A suggestion was made to break out the core component that needed the cleaning and replace it with a roll-in/roll-out standalone component. This allowed the machine to be shut down, the old component rolled out in a matter of minutes and a cleaned component rolled in. The dirty component was then cleaned and made ready for the next changeover. The overall setup time went from approximately one hour to just 6 minutes.

Frequently Asked Questions (FAQ) about SMED

Does SMED really mean a single minute to replace dies?

No. The concept of a single minute means a single digit minute. In other words, a changeover less than 10 minutes.

What is the difference between an internal and external element?

An external element or activity can be done in parallel while the equipment is still running. An internal element or task must wait for the machine to be shut down before doing it.

Besides Shingo, who else did pioneering work in reducing turnover times?

Frederick Taylor analyzed non-value-adding parts of setups in his 1911 book, Shop Management. Frank Gilbreth also looked into changeovers. In his 1911 book Motion Study, he described approaches to reduce setup time. In a 1915 publication Ford Methods and Ford Shops, setup reduction approaches were described.