Cp is a common measure used in process capability analysis, which allows you to know how well your process is meeting your customers’ expectations and specifications. This article will explain how Cp is calculated and interpreted. We will explore its application, benefits and provide some tips and best practices so that you can begin assessing how well your process is doing when measured against the requirements specified by your customer.

Overview: What is Cp?

Process capability is the quantifiable comparison of the Voice of the Customer (specs, requirements or expectations of your customer) and the Voice of the Process (control limits). The goal of process capability is to come up with a quantified measure that informs you as to whether you are meeting your customer expectations or not — as well as a relative value of how well you are meeting or how badly you are missing.

Besides Cp, or capability potential, there are a number of other process capability metrics. They are Cpk, Pp, and Ppk.

Cp, or capability potential, is a measure of the potential capability with the assumption that the distribution of the sample process data is normally distributed and centered within the customer’s upper specification limit and lower specification limit. It represents the best the process capability can be for the specs and process distribution. If there is only a one-sided spec, then Cp cannot be calculated.

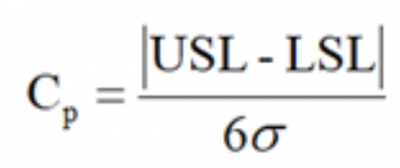

The formula is:

You can say this as Cp is equal to the customer’s upper specification limit minus the lower specification limit divided by 6 standard deviations.

We are assuming that the sample distribution is normally distributed, and its width is calculated by adding and subtracting 3 standard deviations on either side of the sample data mean. The standard deviation that is used is called a “pooled standard deviation” or “within variation.”

Cp can take on values equal to 1, greater than 1, or less than 1.

- A value of 1 would mean the width of the distribution is equal to the width of the specifications, or specs.

- A value greater than 1 would mean the specs are wider than the distribution of the process, so we are comfortably within spec.

- If the value is less than 1, it means the width of the process distribution is wider than the specs, and items will be outside the specs.

But, all of this assumes that the process is centered within the specs — this is rarely the situation. More often than not, the process mean (x-bar) will not be centered within the specs. Interestingly, if the process mean is off-center, the Cp will still be the same since the Cp does not consider the location of the process. That’s when we need to use the Cpk to assess the process capability.

3 benefits of Cp

Cp is a simple and useful metric for comparing your process with your internal or external specifications, targets, expectations, or any other desired outcome for your process.

1. Simple yet powerful calculation

To compute your Cp value, you only need to know the standard deviation of your data and the specs that you want to test against.

2. Can account for a process centered within the specs

If the process is centered within the specs, you would use the calculation of Cp to assess the potential of your process capability. But, as it is in most cases, if the process is shifted off-center, then the Cpk will account for that shift.

3. Can be used to compare different processes

The Cp allows you to compare the performance of disparate functions since it is a generic measure of the process’ ability to meet specs. If a manufacturing line had a Cp of 0.82, and a finance department had a Cp of 1.89, you could say that finance is doing a better job of meeting their customer’s requirements than is manufacturing.

Why is Cp important to understand?

Meeting your customers’ expectations and requirements is vital to your organization staying in business. By understanding how to compute Cp and interpret its value, you will be able to know what to do to meet and possibly exceed your customers’ expectations.

Know what variables are needed to calculate Cp

If you intend to use Cp for decision making purposes, you need to know what variables are needed and what their values are so you can do the proper calculations.

Cp represents your current state process capability

If your Cp is not high enough to satisfy your customers’ specs, you need to take action so that out-of-spec products are not produced and shipped.

You might want to adjust the specs

If you’re not meeting specs, you might want to speak with your customer to see if they can be adjusted without any negative impact. You can use the current Cp calculation to back into what level of specs you’re able to meet.

An industry example of Cp

A coffee company was having a problem with overfill and underfill on their jars during manufacturing. Underfill is a big problem because if the quantity is below the required amount, there could be a recall and significant fines. Overfill is also an issue because it means you’re giving away extra product that the company doesn’t get paid for. The process Cp was 0.79, which meant that the width of the process distribution was wider than the allowable specs. Out-of-spec product was being produced on both ends.

The company put two of its Lean Six Sigma Black Belts on a project to reduce the variation of the process with the goal of narrowing the process distribution and pulling both ends into spec. The project was successful, and the Cp was now calculated as 1.74.

Since the process was now tight within the specs and still centered, the plant manager decided to adjust the process, so the mean of the distribution moved closer to the lower spec. The process distribution was still well within the specs, and nothing fell outside the lower spec. Less coffee was being put into the jars, so the profit per jar increased.

3 best practices when thinking about Cp

Since Cp is merely a calculation, there aren’t really a lot of best practices but more of a series of hints that allow you to get the maximum value out of the calculation.

1. Do both Cp and Cpk calculations

By comparing the potential capability with the actual capability, you will understand what, if anything, you need to do to be sure you remain in spec.

2. Use the Cp to compare different parts of the organization

The use of the generic Cp metric allows you to compare various functions in the organization. It is a measure of how well each is doing relative to their specs and allows for an apples-to-oranges comparison.

3. Use the Cp to establish strategies to take advantage of a good value

You can consider revising specs or shifting the mean of the process within the specs to take advantage of a good process and high Cp.

Frequently Asked Questions (FAQ) about Cp

What is the difference between Cp and Cpk?

Cp assumes that the process is centered within the specs, while Cpk adjusts for a dynamic shift in the mean of the process.

Can I compare Cp across different departments of the company?

Yes. Cp is a generic measure of how well a department is doing relative to its required specs. You can state that Department A is doing better at meeting specs than Department B if Department A’s Cp is higher.

Other than Cp, are there other common measures of process capability?

Yes. You can also calculate Cpk, Pp, and Ppk to measure process capability.

So, what is Cp again?

Cp is a common measure of a process’s ability to meet customer expectations, primarily specifications. It assumes that the process data is normally distributed and that the mean of the process be centered if there are upper and lower specifications.

It is calculated by finding the difference between the upper and lower specification. That difference is then divided by 6 standard deviations. The higher the value is, the better the process capability.

Knowledge and understanding of your Cp value can be a powerful tool for gaining competitive advantage and improved profitability. It can be used for any process with stated specs or qualitative expectations and can also be used as a comparative tool across different functional areas.