SoPK was the culmination of Dr. W. Edwards Deming’s decades of contribution to transforming and improving the management system of all organizations. This article will explore the four key components of SoPK and how they can be applied to your organization.

Overview: What is the System of Profound Knowledge?

Dr. William Edwards Deming (1900-1993) was an American engineer, statistician, professor, author, lecturer, and management consultant and one of the most influential industrialists of the 20th century. He was responsible for introducing the quality systems that drove the transformation of Japan following World War II.

Deming’s philosophy of focusing on quality ahead of production was adopted by the leaders of Japanese industry and led to the development of such successful production systems as the Toyota Production System (TPS). Later on, his work influenced the rise of Six Sigma.

SoPK is composed of four components in which Deming said the world should be looked at.

Deming summarizes SoPK as:

“The System of Profound Knowledge provides a lens. It provides a new map of theory by which to understand and optimize that we work in, and thus to make a contribution to the whole country.” He went on to say, “One need not be eminent in any part of profound knowledge in order to understand it and to apply it. The various segments of the system of profound knowledge cannot be separated. They interact with each other….”

Deming’s 14 Points of Management served as the basis for The System of Profound Knowledge. These 14 points, as described in Deming’s book “Out of the Crisis,” are:

- Create constancy of purpose toward improvement of product and service, with the aim to become competitive, to stay in business and to provide jobs.

- Adopt the new philosophy. We are in a new economic age. Western management must awaken to the challenge, must learn their responsibilities, and take on leadership for change.

- Cease dependence on inspection to achieve quality. Eliminate the need for massive inspection by building quality into the product in the first place.

- End the practice of awarding business on the basis of a price tag. Instead, minimize total cost. Move towards a single supplier for any one item, on a long-term relationship of loyalty and trust.

- Improve constantly and forever the system of production and service, to improve quality and productivity, and thus constantly decrease costs.

- Institute training on the job.

- Institute leadership. The aim of supervision should be to help people and machines and gadgets do a better job. Supervision of management is in need of overhaul, as well as supervision of production workers.

- Drive out fear, so that everyone may work effectively for the company.

- Break down barriers between departments. People in research, design, sales, and production must work as a team, to foresee problems of production and usage that may be encountered with the product or service.

- Eliminate slogans, exhortations, and targets for the workforce asking for zero defects and new levels of productivity. Such exhortations only create adversarial relationships, as the bulk of the causes of low quality and low productivity belong to the system and thus lie beyond the power of the workforce

- Eliminate work standards (quotas) on the factory floor. Substitute with leadership.

- Eliminate management by objective. Eliminate management by numbers and numerical goals. Instead substitute with leadership.

- Remove barriers that rob the hourly worker of his right to pride of workmanship. The responsibility of supervisors must be changed from sheer numbers to quality.

- Remove barriers that rob people in management and in engineering of their right to pride of workmanship. This means, inter alia, abolishment of the annual or merit rating and of management by objectives.

- Institute a vigorous program of education and self-improvement.

- Put everybody in the company to work to accomplish the transformation. The transformation is everybody’s job.

Let’s examine these four components and understand what Deming meant by them on how you may apply SoPK to your organization. The four components are:

- Appreciation of a System: All businesses consist of a system comprising the business itself, its employees, suppliers, customers, and various other entities. Action in one part of the system will have an effect on the other parts. Deming called those effects “unintended consequences.” By better managing your system, you can mitigate these unintended consequences and optimize the whole system.

- Knowledge of Variation: All processes vary. A major goal of Six Sigma is to reduce variation. Critical to understanding variation is the knowledge that there are two types of variation — common cause, which is variation from the system, and special cause, which is variation from outside the system. Deming felt it critical for managers to understand the difference, because those who do not understand variation frequently and inadvertantly increase process variation by their actions of tampering with the process.

- Theory of Knowledge: There is no knowledge without theory. Understanding the difference between theory and experience prevents shallow change. Theory requires prediction, not just explanation. While you can never prove that a theory is right, there must exist the possibility of proving it wrong by testing its predictions. Additional thoughts on this element of SoPK are:

- Information itself is not knowledge.

- Without theory, experience teaches you nothing.

- Practice does not make perfect, it only makes it permanent.

- Copying examples does not lead to new knowledge.

- Understanding of Psychology: To understand the interaction between work systems and people, leaders must seek to answer questions such as: How do people learn? How do people relate to change? What motivates people? Leaders must understand human behavior to motivate, coordinate, and manage people to optimize the system. A leader should make an effort to understand people and how they best work in the organization’s systems. A leader should leverage knowledge of psychology to better understand what motivates each individual on the team – what motivates one, may not motivate the other. In his final years, Deming focused on the “psychology of change.” He recognized that it was exceedingly difficult to transform a company to operate by the principles he taught without considering the psychology and behavior of people.

Deming summarized his principles for transformation from the present style of Western management to one of optimization with the following guidelines:

- Providing a new, outside view

- Transforming managers to leaders

- Increasing quality, customer loyalty, worker satisfaction and, ultimately, profitability

- Reducing costs by reducing waste, rework, and staff attrition and litigation

- Removing fear and competition from the workplace and classroom

- Realizing the power and pleasure derived from intrinsic motivation

- Cultivating the value and results of cooperation and collaboration

- Thinking in new ways and taking action based on confirmed knowledge

- Understanding the importance of a better system for achieving better outcomes

- Working towards continual improvement — individually and collectively

- Supporting individuals and organizations through the first disruptive steps of transformation

- Creating opportunities for continued, lifelong learning to bring long-term meaning satisfaction and joy

- Addressing different learning styles (generational) and cultivating the next generation of leaders

3 benefits of using the SoPK

Deming talked about revolutionary change in management philosophy, not just evolutionary. These are some of the benefits of using SoPK for organizational transformation.

1. Holistic roadmap for transformation

Deming not only provided us SoPK, but also the 14 Points and 7 Deadly Diseases and Obstacles for transforming an organization.

2. Focus is on what management needs to do

SoPK is specific in the required actions of management which are required to successfully implement his principles for an optimized system.

3. Flexible and applicable to all organizations

All organizations can benefit from the application and implementation of SoPK.

Why is SoPK important to understand?

SoPK and Deming’s other management principles are complex. They require a full commitment and understanding to fully make the transformation.

What, not how

SoPK doesn’t tell you exactly how to implement the changes Deming recommends, but they do provide sufficient information about what to change.

Comprehensive

Understanding of SoPK includes knowledge about Deming’s 14 Points as well.

Takes time to transform

One of Deming’s favorite sayings was, “It does not happen all at once. There is no instant pudding.”

An industry example of SoPK

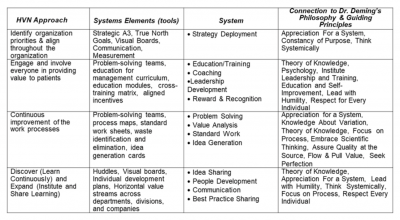

Healthcare Value Network, a healthcare peer to peer network, developed a principle-based framework to guide and accelerate the cultural transformation efforts of their members through design and redesign of systems.

The principles are based on Dr. W. Edwards Deming’s System of Profound Knowledge. They also included lean enterprise principles developed by Shigeo Shingō (1909-1990), a Japanese industrial engineer who was heavily involved in the development and promotion of the Toyota Production System (TPS).

This chart shows the four core components, the tools used, and the integration of SoPK. Member organizations who made the transformation are now providing better patient-centered care in a more cost-effective manner.

3 best practices when thinking about SoPK

The transformation of how your organization works is not a simple nor quick task. Here are a few hints on how to make the journey a little less arduous.

1. Senior leadership

Without the full commitment, participation, and leadership of top management, transformation will not occur.

2. Don’t try to change everything at once

SoPK and Deming’s other teachings are very comprehensive. Start with a limited approach and build upon your successes.

Deming summed this up nicely by saying, “Long-term commitment to new learning and new philosophy is required of any management that seeks transformation. The timid and the fainthearted, and the people that expect quick results, are doomed to disappointment.”

3. Get outside help

Deming believed a system cannot understand itself without help from outside because prior experiences will bias objectivity and prevent critical analysis of the organization.

Frequently Asked Questions (FAQ) about SoPK

1. What are the four components of SoPK?

The four components of Deming’s System of Profound Knowledge are:

- Appreciation for a system

- Knowledge about variation

- Theory of knowledge

- Knowledge of psychology

2. Who developed the System of Profound Knowledge?

Dr. W. Edwards Deming, famed statistician and quality consultant.

3. What does Deming mean by “theory of knowledge”?

A manager who makes decisions by intuition or experience can get in trouble when that leader’s experience or intuition is limited, or doesn’t apply to the problem at hand. ‘’

Deming said, “Knowledge is theory. We should be thankful if action of management is based on theory. Knowledge has temporal spread. Information is not knowledge. The world is drowning in information but is slow in acquisition of knowledge. There is no substitute for knowledge.”

Recap of SoPK

SoPK is the culmination of the work of Dr. W. Edwards Deming. It was his life’s mission to help organizations transform from current Western management practices to one of improvement, innovation, and optimization.

His SoPK has four components. Everything is a system that requires an understanding of variation where management actions require a knowledge of theory and not just experience and intuition. Knowledge of psychology is required to motivate and lead people to achieve the best they can be.

Deming believed “A bad system will beat a good person every time,” and “people are entitled to joy in work.”