Key Points

- The I-P-O model allows you to simplify the inputs, processes, and outputs of a given workflow.

- The model fits readily into DMAIC, fitting squarely into the Define stage.

- It is an easy and visual tool that anyone can use.

- This model doesn’t consider the voice of the customer.

- It is a perfect starting point for more involved process maps.

Implementing I-P-O into your current projects can be a fast and visual way of understanding workflow. While it can seem daunting to adopt a new methodology, you don’t need to worry. Putting this methodology into action is quick and simple, as you’ll see throughout our guide.

Overview: What is Input-Process-Output (I-P-O)?

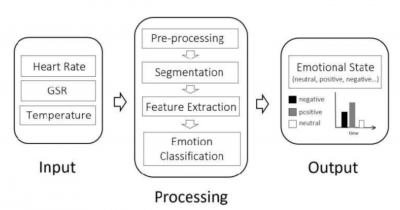

Input-process-output (I-P-O) is a structured methodology for capturing and visualizing all of the inputs, outputs, and process steps that are required to transform inputs into outputs.

It is often referred to, interchangeably, as an I-P-O model or an I-P-O diagram, both of which refer to the intended visual nature of the method.

A simple example is shown below from healthcare research.

As the methodology is incredibly versatile, it is used across many industries and sectors with (inevitably) some modifications and adaptations. These can include, for example, the addition of feedback loops from output to input, in doing so creating models analogous to closed-loop control theory.

Putting I-P-O To Use

Typically, we would use I-P-O in the “define” stage of a Six Sigma DMAIC project and follow a specific method for generating the model. The steps are:

- Decide upon the process steps that will be in the scope of the model. Try to ensure the scope is manageable with, ideally, less than 10 process steps defined.

- List all of the possible outputs, including potential error states.

- List all of the inputs to your process steps, using clear descriptive language.

- Create a visual model.

- Check that the inputs transform into the outputs via the process steps as shown in the model.

Often, it can be helpful to have the team that’s generating the I-P-O model complete a Gemba walk. Further, visiting the actual place of work, and subsequently viewing the process in action can tease out some of the less obvious inputs and outputs and contribute to continuous improvement of the existing process steps.

2 Pros and 1 Con of I-P-O

Used correctly, the I-P-O model offers a simple, practical, and efficient way to analyze and document a transformation process. Let’s explore some benefits and drawbacks of the methodology.

Pro: Visual and Easy to Explain

The best business improvement tools are simple to use, intuitive, and visual. Thankfully, I-P-O ticks all three of these boxes. A sheet of paper, a marker pen, and an enthusiastic team willing to contribute will get you a long way. Additionally, it’s also versatile and suitable for use with the executive management group as well as the wider business improvement team.

Pro: Easy to Execute

There is a clear and simple methodology to generate I-P-O models, and this helps you recognize and document all of the possible inputs, outputs, and error states. Since it’s visual, it’s easy to update and change as the team explores many potential inputs and outputs.

Con: An Internal Focus Doesn’t Consider Customers or Suppliers

Usually, developing I-P-O models is all about internal business processes, and we often hear this called micro-process mapping. As such, this typically means we do not consider our external suppliers and customers in the analysis. However, don’t worry, we have complimentary models such as SIPOC and COPIS that help us make sense of the bigger picture.

Why is I-P-O Important to Understand?

While this is such a relatively simple mapping tool, it provides a really powerful insight into our internal business processes. Let’s dig a little deeper.

It Helps with Defining Your Key Process Input Variables

Once we’ve documented and visualized our inputs and outputs, we can turn our attention to determining and controlling which inputs provide a significant impact on the output variation — these are known as our key process input variables.

It’s Aligned with Six Sigma and Lean Principles

In a classic Six Sigma and Lean project approach, we strive to reduce process variation and remove defects and waste. With this methodology, we identify inputs, outputs, and error states from our processes so we can begin to explore and understand the Y(output) = f ((X) input) equation.

It’s the Perfect Springboard for Creating Full-Process Maps

Once we have created I-P-O models, we have the perfect starting place for generating complete process maps. This could be moving on to value stream mapping, spaghetti maps, or one of many other types of process maps that are available.

An Industry Example of I-P-O

A government agency with multiple departments was embarking upon a business transformation project to improve customer service times and efficiency. As part of the transformation project, a Six Sigma Black Belt who was assigned to the activity was requested to explore and document existing processes and prepare the teams for process improvement.

The Black Belt chose to create I-P-O models due to the ease of use and versatility of the approach. Each of the business departments designated a team to work on the I-P-O models and, alongside the Black Belt, defined the process scope, ensuring this was of manageable size.

With the teams in place and scope defined the process outputs were brainstormed and captured visually using whiteboards. The corresponding inputs were added. Afterwards, the I-P-O models were checked for completeness.

Further. generating the I-P-O models highlighted several potential output error states. These were subsequently investigated as part of the business transformation project and contributed to improved customer service times. Since the models were captured visually on whiteboards, they were easily updated during the project and used to inform staff of their contribution towards continuous improvement.

Real-World Uses of I-P-O

While you likely have I-P-O understood at this point, let’s break it down to its barest elements. Additionally, you can readily apply this model to the processes contained. With this in mind, let’s consider how the model applies to something banal, specifically brewing a cup of coffee.

As such, how would you apply this model to a cup of coffee? Consider what you need to do to brew the coffee. You can break it down like this:

- Input: You pour in your grounds and press brew

- Processing: The machine ticks to life, brewing the cup of coffee with your preferred settings.

- Output: A cup of coffee is ready, and an alert sounds off to signal it is ready.

Furthermore, this model can be applied to much broader processes, like manufacturing.

3 Best Practices When Thinking About I-P-O

Like many process-driven mapping activities, there are some key things for us to consider when creating I-P-O models. Let’s look at three of these.

It’s a Team Sport; Don’t Go it Alone

Even relatively simple processes have multiple inputs and outputs. Further, we often find that different team members have detailed knowledge of specific process inputs and outputs. Understandably, we should make good use of this collective knowledge.

Make Sure the Scope Is Achievable

Don’t be overly ambitious with the scope and try to include too many process steps for your I-P-O model. As such. if you find yourself listing 10 or more process steps, it’s probably time to stop and re-evaluate.

Consider All of the Inputs and Outputs

Be diligent, get all the team involved, and make sure there is no bias — we don’t want to just list the things we think should be inputs and outputs in an ideal world. Further, we should consider and document all of the possible output error states.

Additional Tools for Mapping Your Projects

While I-P-O is a useful tool for mapping out a project, it is limited in what it can do. As such, you might want to look into process mapping. That said, you can see how process mapping has benefited the California High-Speed Rail Authority.

With that in mind, there is no shortage of management systems for your processes. As such, you can see the full tools at your disposal with our exhaustive guide on business process management systems.

A Final Thought on I-P-O

Ease of use and versatility are just two of the major plus points of developing I-P-O models for your internal business processes. As such, once you add in their highly visual nature, this means you can easily engage your team on a journey to continuous improvement.