PSW Key Points

- PSWs are a necessary and mandatory document in the PPAP process.

- Understanding how to properly submit a PSW builds trust with your client.

- Depending on the materials requested, your PSW may need additional documentation.

- A Part Submission Warrant is a proven and tested process and is required in certain industries.

- Consult with your team before submitting a PSW.

Overview: What is a Part Submission Warrant, or PSW?

A Part Submission Warrant document or form is used to confirm that the supply of components meets the customer’s requirements.

The document is a fundamental part of a managed quality process called the Production Part Approval Process (PPAP). It contains a summary of the entire PPAP documentation. Manufacturers may provide a PSW template for their suppliers to use. Further, this can help ensure that the document contains the correct information.

The supplier will complete and send the PSW document to the customer for review along with the required PPAP documentation. Assuming the customer accepts the submission, they will sign and return the PSW document confirming product acceptance.

Why Are These Needed?

A PSW document is required by the customer whenever a product or process change is implemented. Subsequently, any changes can affect or impact customer requirements. This could be a relatively trivial design change with no or low risk. It could also be a fundamental material and manufacturing change with high risk to the customer. To help differentiate between these several levels for both PSW and PPAP are defined and shown below.

- Level 1: Only the PSW document is required. An example could be a non-critical design change leading to a part number change.

- Level 2: PSW with product samples and limited supporting data from the PPAP.

- Level 3: PSW with product samples and complete supporting data from the PPAP.

- Level 4: PSW and other requirements as defined by the customer (in addition to Level 3)

- Level 5: PSW with product samples and complete supporting data available from the PPAP for review at the supplier’s manufacturing location. An example could be the introduction of a new material and manufacturing location.

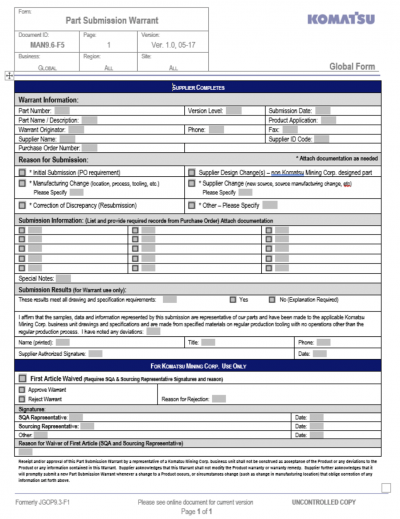

A typical PSW document will include fundamental information such as:

- Part numbers and part descriptions

- Engineering changes

- Materials and compliance with regulatory health and safety requirements

- Test result summaries

Importantly, you must also include declarations that all of the information provided is wholly representative of the parts being supplied. As such, here we have in essence the very meaning of PSW. It is a document that the parts submitted meet the customer’s requirements and functional specifications.

A relatively simple industry template is shown below to illustrate what may be required when completing a document.

Image source: Part submission warrant – Komatsu

Pros and Cons of the PSW

Filling out more forms and documents is just an unnecessary overhead, right? Time to think again and look at some benefits and drawbacks of these documents.

It Is a Mature and Proven Process

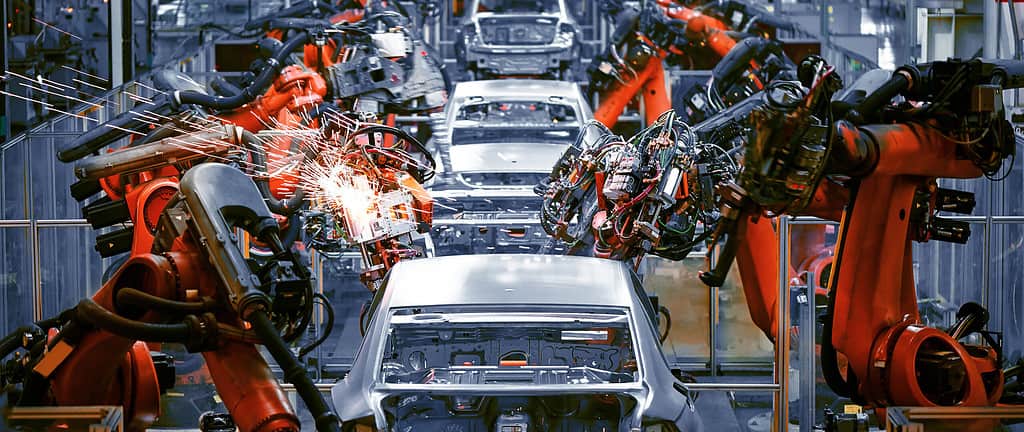

The PSW document is one very important part of a mature quality process that has been developed in industries such as automotive and aerospace to ensure compliance with customer requirements.

Adherence Enables Success in Competitive Industries

As a supplier wishing to either enter or continue being successful in the automotive or aerospace industries, understanding the requirements of a PSW document is one of your key enablers.

Con: It Takes Resources and Time to Generate a High-Quality Document

Don’t underestimate the time and resources required to complete a high-quality PSW document. Even with company-specific templates, make sure you set aside sufficient time and assign people with the right skill set.

Why Are PSWs Important to Understand?

The creation of a PSW document is a non-negotiable requirement when delivering your parts to the industry, so it pays to get it right.

It Forms Part of a Quality Management and Delivery System

The PSW document contains the summary of compliance with all the customer requirements and is officially submitted to the customer for review and acceptance. The customer will review, sign, and return the PSW indicating acceptance of your quality management and delivery.

It’s a Fundamental Requirement for Many in the Automotive Industry

Most automotive and aerospace companies insist that their suppliers follow a specific Production Part Approval Process with associated PSW documents. Noncompliance typically means you lose your competitive advantage and contract of supply.

Errors in Submission Have Big Negative Impacts on Resources

It takes a significant amount of time to bring together the PSW document, so diligence is key. Always review the document internally before submission to the customer. Non-acceptance of PSW documents leads to intensive rework – especially to maintain original product delivery timescales.

An Industry Example of PSW

A Tier 1 supplier to the automotive industry providing starting aids for diesel engines was investigating an increase in warranty returns. The Six Sigma Black Belt assigned to the investigation, along with the engineering team, concluded that the root cause for failures in the field was the material composition of the interface washer between the starting aid and cylinder head. In a discussion with the customer, it was agreed to change the interface washer material composition, and trials were conducted showing the root cause had been addressed.

As the interface washer was supplied pre-assembled to the starting aid and previously not available as a standalone service part, several changes to the PPAP and PSW documents were required. Close cooperation between Tier 1 and the OEM led to an agreement that the changes would require a Level 3 PSW submission, with product samples for both production and service and complete supporting data from the PPAP.

Trials were completed at both the engine production plant and in the dealer network and were concluded successfully. Further, the PSW documentation identified the new part numbers and compatibility for the original fit and service use. PSW documentation was signed off on, and the Tier 1 supplier was then able to revert to supply at full production rate

Is a PSW Needed?

If you’re new to this concept, it can seem a bit much at first blush. So, why exactly are part submission warrants needed in the first place? These are dense and detailed documents, but are a necessary and crucial element to any production, depending on the industry. If you’re looking at mission-critical components, they are an absolute requirement.

So, let’s consider why you need it to begin with. Consider for a moment that you’re in charge of equipment in the server closet of a major financial institution. You’re tasked with keeping track of the workstations, the servers, and all their various components.

Downtime is paramount to death, essentially, as any time these machines go offline you’re losing money. As such, when something like a server goes belly up, you’ll have to replace it. Using a Level 3 Part Submission Warrant as an example, you would need to provide documentation on why this is a mission-critical element in your workplace.

Any changes have to be documented, especially when you’ve got money on the line. By providing supporting materials, you’re fulfilling the PPAP with your supplier and making sure you’re keeping a server running with minimal downtime.

Best Practices When Thinking About PSW

As with many process-based activities, there are some fundamentals to consider to ensure correct and timely delivery. Let’s explore three of these.

It’s a Team Sport; Don’t Go It Alone

The PSW document touches many areas of the business, from design to manufacturing and quality. Make sure you have the right resources and team assigned.

Start Preparing Early, and Be Methodical

The PSW document is intended to be a summary of all the elements that show you are meeting your customer requirements. As such, plan early, and never leave this until the end of development and manufacturing, especially if you are providing product samples.

Communicate and Check in Regularly with your Customer

Often, large organizations have specific PSW templates that you should use, and it’s always good practice to check that your submission is meeting the document requirements ahead of delivery.

Other Useful Concepts and Tools

Are you still with me? While we’ve spent most of this guide focusing on the minutia, it is handy to take a break and consider some other useful elements to integrate into your workplace. Your industry doesn’t necessarily matter in this scenario, as these concepts can be applied across the board.

No matter the industry, you’ve got customers. So, how do you engineer your products or services for success? Why not consider implementing Critical to Quality in your organization? This customer-driven approach helps you focus on developing the best possible deliverable that meets your customer’s needs.

Additionally, you might be looking to minimize defects in the production line. Understanding how Sigma Levels apply to production, especially during the analysis stage is a useful and vital concept to master. Our comprehensive guide covers how Sigma Levels factor into your process workflow.

Wrapping Up

Part Submission Warrants are a vital component of any manufacturing industry. When it comes to guaranteeing your deliverables, you want every step of the process to be iron-clad. Failing to do so could cost you your customer’s trust and tarnish your organization’s reputation in the process.