The roadmap has always been an important part of Six Sigma. It lays out the thought process for teams and leaders, and distinguishes the methodology from a parade of tools. With the original “Six Steps to Six Sigma” and then “Define Measure Analyze Improve Control” (DMAIC) as the improvement roadmap, plus the addition of Design for Six Sigma (DFSS), practitioners have evolved and expanded their view of how the steps and tools fit together and deliver results.

To make things interesting, DFSS is a lot less standard around the world than DMAIC. Roadmaps like “Define Measure Analyze Design Verify” (DMADV), “Invent/Innovate Develop Optimize Verify” (I2DOV) and “Concept Design Optimize Verify (CDOV) are similar in spirit, but with differences in nuance and detail. Add to this the common desire to map in other initiatives, like Lean and Business Process Management, and it’s easy to see why companies sometimes think about rationalizing and perhaps simplifying their roadmap view.

While there are numerous coexistence and integration questions, a combined core DMAIC-DFSS roadmap is possible.

How to Deal with Two Roadmaps?

Many companies begin their Six Sigma work with DMAIC problem-solving and improvement. This makes sense as DMAIC brings rapid improvement to existing processes – quickly returning significant dollars to the bottom line. Because DMAIC projects often point to problem root causes in the design of products or processes, interest in DFSS often develops in connection with improvement work. Thus leaders may find themselves struggling to manage two Six Sigma approaches and roadmaps.

In a world where “innovate and design” are naturally separated from “improvement work,” two roadmaps may work just fine. In many real-world cases, though, design is often interwoven with existing products and processes, and improvement often means revisiting fundamental design. In those situations, the project teams, Belts and Champions can waste energy worrying, “Is this a DMAIC or DFSS project?”

The Appeal – and Challenge – in Integrating DMAIC and DFSS

When a company feels that too much time is being spent sweating out the distinctions between DMAIC and DFSS, it may move to integrate and simplify things. Experienced Six Sigma practitioners may notice that the thought processes have some parallels, especially in the Define and Control phases. While it is tempting, and even possible, to integrate the approaches in new and creative ways, it is best to use some common approaches with an eye toward caution. Integrating the roadmaps requires special attention to the subtle ways they are different.

(For the purposes of this article, the common DMADV map is used as the frame of reference for DFSS.)

“Everything Is DMAIC”

Perhaps because people are more familiar with DMAIC, they seek to use it as the foundation for integration, with DFSS seen as a special sidebar. At one extreme, companies move to integrate with the theme, “Everything Is DMAIC+/-.” They view the DFSS distinction in the scope and nature of the improvement or innovation work that happens between the Analyze and Control phases. An accompanying theme is often “D, M and A Are the Same for All Projects.” The thinking is that during Analyze, a team figures out whether improvement or design is called for and they pursue an I-phase that tracks with either DMAIC (improvement) or DFSS (innovation/design). As Figure 1 depicts, after that roadmap branch, the similarities between DMAIC’s Control phase and DFSS’s (DMADV) Verify phase often bring things back together for a common last stage.

Risks in Viewing “D, M and A” as Identical for All Projects

While the high-level thought process for D, M and A are parallel for DMAIC and DMADV, they are not at all the same in practice. The mindset of a team and the nature of its curiosity in data gathering and analysis are different through D, M and A for projects with DMAIC scope versus DFSS scope. DMAIC problem-solving calls for a “detective” orientation, looking for clues and focusing on specific root causes. Innovation/design calls for an “anthropologist” orientation, looking for how people do things (or could do things), clues about latent requirements and measures that identify performance drivers. While both of these orientations move through a “D, M and A” stage, they have a different scope and flavor. Figure 2 illustrates the view that every stage, not just the I-phase, sits against a backdrop that could be Improvement (DMAIC)- or Design/Innovation (DFSS)-oriented. While the names of the steps, and in many cases the tools, are the same for all projects, a team’s practical work is guided by a project’s location on the improve-innovate continuum.

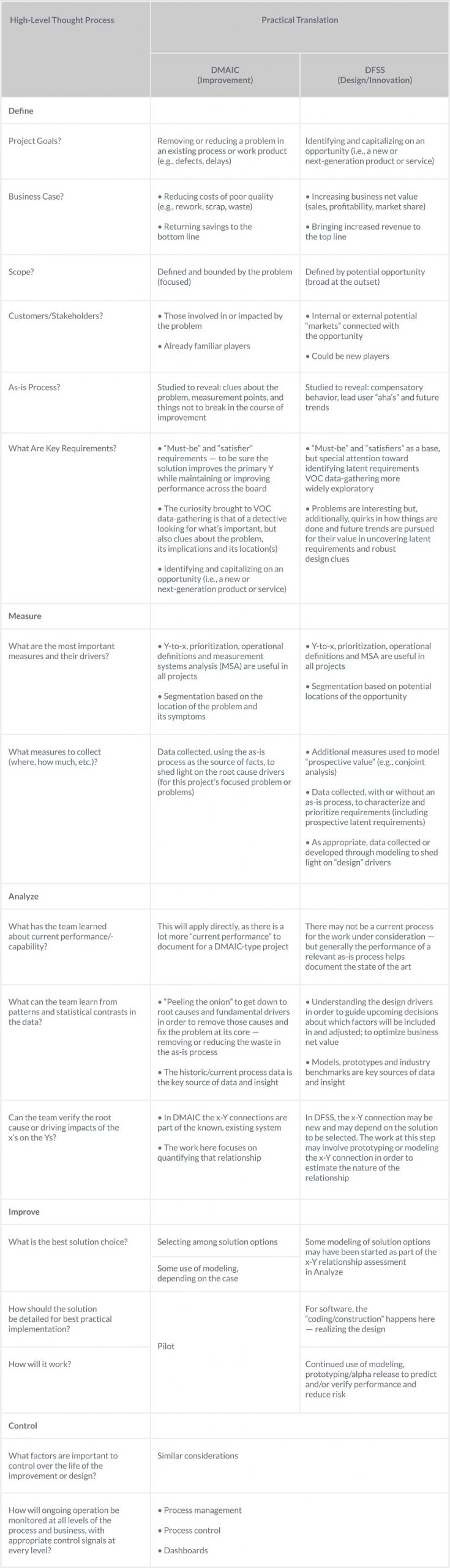

Aligning DMAIC and DFSS With Attention to the Distinctions

The table below depicts a simplified view of what happens if the DMAIC and DMADV thought processes are distilled to a high enough level that one map might be laid out. The “Practical Translation” columns show distinctions that would be important to a particular team, depending on whether its current project was DMAIC or DFSS (or somewhere in the middle). The intended takeaway from this view is that D, M and A are where many of the DMAIC and DFSS distinctions lie. While they can be overlaid, it is important for each project to understand as early as possible where it is on the DMAIC-DFSS continuum. Some projects start out “thinking they are DMAIC” only to find (somewhere in D, M, A or I) that they are really more DFSS – or vice versa. The table is a first step in guiding a team toward the correct “edge,” no matter where on the map the team was when the project’s nature became clear.

Conclusion: Being Well-Armed with Insight

All practitioners appreciate that roadmaps are needed to guide the work in Six Sigma, and that there is an understandable need to simplify and integrate when their complexity starts to get in the way. While considering a “branched” and a “parallel” approach to integrating DMAIC and DFSS, one must be armed with as much insight at possible before deciding what is best in their particular environment.