Tag: DMAIC

PDCA vs. DMAIC: What’s the Difference?

Published:What are the differences between PDCA and DMAIC? There is no shortage of jargon and acronyms to keep track of within the Six Sigma methodology. However, the two methods we’re looking at today blur the lines substantially. So, let’s jump in and see exactly how these approaches differentiate themselves. What is PDCA? Plan […]

Read more »

Progress Check: The Importance of Tollgate Reviews in Project Management

Published:Do I have to pay money to get through my project Tollgate? Of course not, but you do have to stop, evaluate your progress, and make sure you’re still heading in the right direction — and accomplishing the tasks required for each step of your project.

Read more »

Mastering Process Improvement Through Y=f(x) Methodology

Published:Y=f(x) is a concept regarding the setup of a formula used to perform analysis during problem-solving efforts. Let’s look at how Y=F(x) works within the problem-solving process, the benefits of Y=F(x), as well as some frequently asked questions.

Read more »

Design For Six Sigma (DFSS) vs. DMAIC: What’s the Difference?

Published:One of the most confusing issues associated with someone saying “I’m using Six Sigma” has to do with what methodology they are using. A majority of the time they are using the DMAIC methodology because they have existing processes that are wasting resources (hence the big savings you’ve heard about at GE, Honeywell, […]

Read more »

1.5 Sigma Process Shift: What It Means For Your Business

Published:Why is 6 sigma 3.4 ppm, not 2 ppb? The calculation of process sigma after a process improvement project should be reported as short-term sigma.

Read more »

What Is DMAIC?: Master Your Process Improvement

Published:DMAIC refers to a data-driven quality strategy for improving processes, and is an integral part of the company’s Six Sigma Quality Initiative. DMAIC is an acronym for five interconnected phases: Define, Measure, Analyze, Improve, and Control.

Read more »

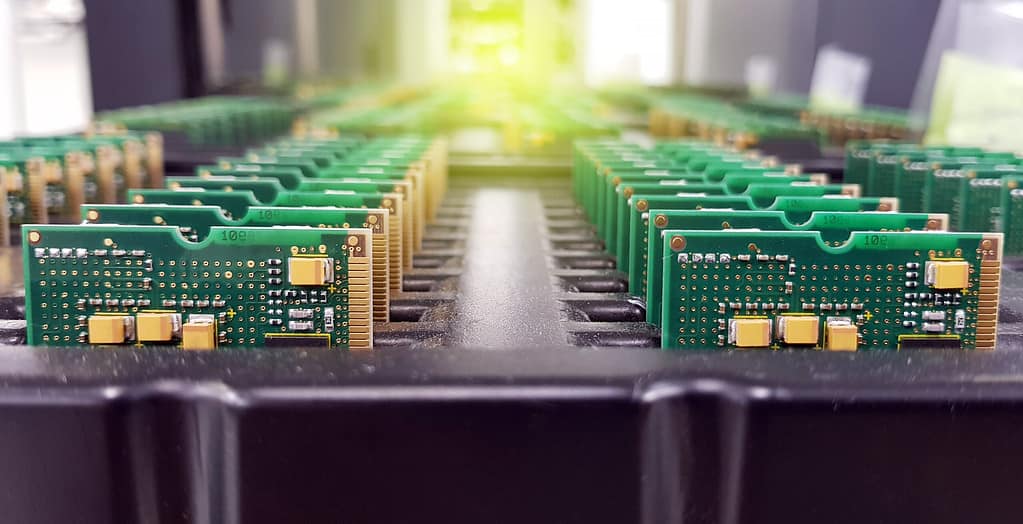

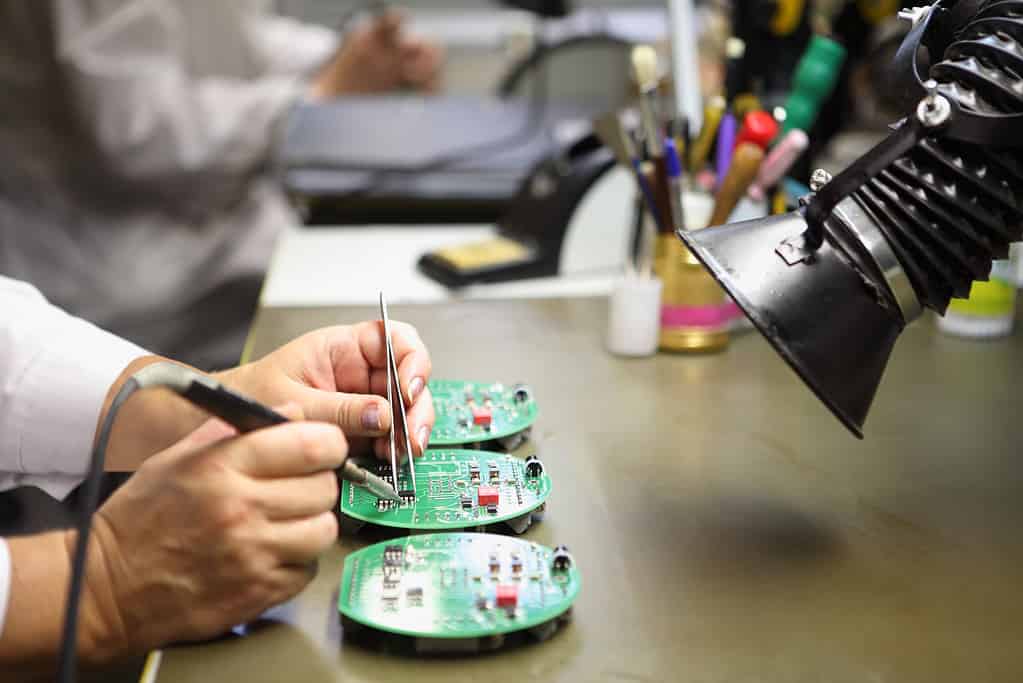

Motorola Uses Data-Driven Six Sigma Methodology to Improve Production Process

Updated:In the early 2000s, Motorola struggled with product defects and a decline in customer satisfaction. To improve its business processes and regain its competitive edge, Motorola turned to Six Sigma. This data-driven methodology for process improvement turned their fortunes around. The Impact of Six Sigma on Motorola’s Semiconductor Production Process Motorola is a […]

Read more »

How Six Sigma and the DMAIC Process Made Samsung Into an Industry Leader

Updated:With strategic implementation, Six Sigma can do wonders for an organization. The methodology can drastically improve processes, cut down on waste, and even help provide better results in the design and R&D of new products. Samsung found that it was having issues with all of the above and, in 1999, conducted a complete […]

Read more »

From Chaos to Order: Reinvigorating a City’s Finance Department

Published:The City of Fayetteville, North Carolina, faced a staffing crisis in its Finance department. Thanks to a DMAIC project, in just 14 weeks the City was able to turn the department’s chaos around.

Read more »

Bank Deposits: A Black Belt Case Study

Published:A Black Belt used Six Sigma to improve a transactional bank deposit process, resulting in yearly savings of $4 million.

Read more »