Category: 5S

Case Study: 5S in Practice

Updated:5S is a Lean tool that helps in workplace organization. The following is the list of five Japanese words and their translation in English. (Seiri) Sorting and prioritizing: Going through all the tools, materials, etc., in the work area and keeping only the essential items. Everything else is stored or discarded. (Seiton) Straighten or set […]

Read more »

Why Practice 5S?

Published:Someone asked: “Why do 5S [sort, simplify, shine, standardize, sustain]? It’s just going to get dirty again.”

Read more »

Streamlining Production with Just-In-Time Manufacturing

Updated:Have you ever had to shut down your manufacturing line because major components haven’t arrived from your supplier? Have you ever had to rent extra warehouses for your finished goods? Just-in-time (JIT) manufacturing would prevent that from happening. Let’s see how that works.

Read more »

Achieving Quality Through Continuous Improvement

Updated:Competition for products and services is cutthroat, and survival should not be taken for granted. Implementing continuous improvement into your organisation and embedding it into your business culture keeps you one step ahead of the pack, locking in both customer and employee loyalty.

Read more »

Resource Page: 5S

Published:During the month of August – while many are taking time off to enjoy summer – we will be offering a resource page on a different topic each week. The resource page features an overview of the week’s topic and links to the best related content across iSixSigma. This week’s topic is 5S. 5S is […]

Read more »

A Model for Implementing a 5S Program

Published:The process improvement tool 5S (sort, straighten, shine, standardize, sustain) sounds like a simple concept to implement – and it is. But its simplicity is sometimes the cause of its early demise – it is easy to “do” 5S without much effort or strategic coordination, and thus without as much effect as possible. A 5S […]

Read more »

Enhancing Work Practices: How Lean 5S Improves Efficiency

Updated:Lean 5S (sort, simplify, shine, standardize, sustain) are about organizing work space so we can be more efficient, effective and productive. All Lean concepts are about how work gets done. There are many benefits Lean 5S can provide including improving safety, decreasing down time, raising employee morale, identifying problems more quickly and establishing convenient work […]

Read more »

No Cause for Alarm: Avoiding Control Room Overload with 5S

Published:The typical plant control room has changed dramatically over the years. Alarm management – which once was simply a sound or flashing light designed to get the control room operator’s attention – has changed dramatically, too. Many control rooms have replaced analog panel boards with multiple screens of bright and colorful representations of plant equipment. […]

Read more »

Continuous Process Improvement Encounters the Fog and Friction of War

Published:Many people in the private sector are aware that the U.S. Air Force is using continuous process improvement (CPI); however, few may know that CPI is utilized throughout the central command area of responsibility in the Middle East and Central Asia – also known as “the war zone.” War is never easy, and the fog […]

Read more »

Lean Six Sigma Remains Strong in Manufacturing

Published:A recently released study of compensation trends at manufacturing companies across the country contained some reassuring news for quality professionals: The deployment of Lean and Six Sigma methods remains strong in the manufacturing sector. Within the more than 1,000 pages of the 2010 Compensation Data Manufacturing survey on salaries and benefits, conducted by consulting firm […]

Read more »

5S as a Tool for Gaining Buy-in

Published:During my experience as a Lean Six Sigma (LSS) practitioner, I have found that it is very important to grab the attention and the interest of participants as quickly as possible. For any Lean program to succeed, participants must immediately identify with and buy into the concepts, and learn how Lean will benefit their lives. […]

Read more »

Ease 5S Sort Process by Defining Necessary Criteria

Published:One of the most challenging concepts in Sort is the differentiation between needed and unneeded items. To make this step clear and easy to implement, it’s important to have a conversation to define what is “necessary” for the organization.

Read more »

A Practical Approach to the Successful Practice of 5S

Published:While some Lean Six Sigma (LSS) practitioners consider 5S a tool, it is more than that. 5S, abbreviated from the Japanese words seiri, seito, seiso, seiketsu, shitsuke, is not just a methodology, it is a culture that has to be built in to any organization which aims for spontaneous and continuous improvement of working environment […]

Read more »

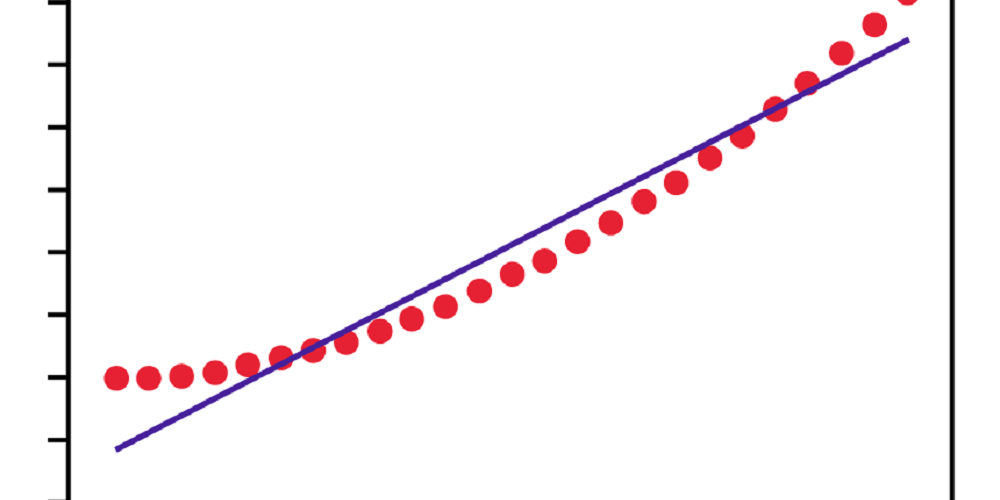

Checking Simple Linear Regression Analysis Using 5S

Published:A twist on the standard 5S to state, select, straight, sweep and stay will help you get the most benefit from a linear regression analysis.

Read more »

Kaizen and Six Sigma Together in the Quest for Lean

Published:Kaizen is seductive and efficient. It can deliver results quickly and on a significant scale, utilize the collective insight and experience of those who know most about the process and inspire employees with a relentless curiosity about and discomfort with waste, defects and constraints to throughput. But it is also overrated. Kaizen Alone In the […]

Read more »

Learning to Think Lean: 6 Steps with Review Points

Published:Organizations can profit from learning to think in terms of Lean, a philosophy that aims to eliminate waste. Learn the six steps to a strong Lean foundation, including detailed questions to ask at each step to review current status.

Read more »

5S Your Email Outbox

Published:After reading my last post, 5S Your Email Inbox, a couple of colleagues asked whether they could apply 5S to sending emails as well. Here are the guidelines that I use – I’m sure others have their methods, too, so feel free to share your own best practices! SORT 1. Ask yourself, does the recipient really […]

Read more »

5S Your Email Inbox

Published:I love to open my business email inbox in the morning, don’t you? Especially if you’ve been practicing good work-life balance and haven’t peeked at it since the end of business the day before. When I go on vacation, it’s a special treat. Here’s a 5S strategy that I have used to keep up with […]

Read more »