isixsigma.com

Regression

Published:A statistical tool which allows you to predict, with varying degrees of accuracy, your output based on the values of your input.

Read more »

DOE

Published:A statistical tool for describing a causal relationship between variables using controlled experiments.

Read more »

Bar Chart

Published:A graph that represents quantified data in the form of discrete rectangular shapes.

Read more »

Quantitative Variable

Published:Quantitative data represents values and numbers which can be measured or counted and used in mathematical operations such as addition, subtraction, multiplication, or division.

Read more »

Engineer Change Order (ECO)

Published:A document that lists details for new product designs or modifications being proposed to current products.

Read more »

5Z

Published:The 5Z process uses the Genba (Gemba) Kanri principles to maintain, evaluate, promote, and improve control of your process.

Read more »

Unexplained Variation (S)

Published:The random fluctuations around the regression line that show as variation. This type of variation is the sum of squared differences between each ordered pair’s y-value and the predicted corresponding y-value. It is the error portion of the regression equation.

Read more »

Customer Relationship Management (CRM)

Published:The union between conventional customer relations and integrated software solutions.

Read more »

Critical Element

Published:An aspect of a work assignment or designated responsibility that is so vital that a less-than-satisfactory showing on that aspect would be deemed unacceptable.

Read more »

Successful Reinvention Focused on Customers and Quality

Published:In 2008, Starbucks was taking a major hit from the financial crisis, losing customers to competitors, and having to close hundreds of stores. Despite having its back against the wall, some decisions made around key Six Sigma principles helped Starbucks bounce back better than ever. How Giving Quality and a Better Experience To Employees and […]

Read more »

Muri

Published:A Japanese word that can be defined as unreasonableness or going beyond one’s power.

Read more »

Global Commerce Initiative (GCI)

Published:A group comprised of trade industry representatives, retailers, and manufacturers worldwide who collaboratively establish best standards and practices in order to improve the international supply chain of goods for consumers.

Read more »

Material Requirements Planning (MRP)

Published:MRP is an integrated logistics plan that encompasses supply chain, storage and availability for particular processes within the scope of the company’s operations.

Read more »

The 2.67 Million Dollar Mystery (And How 5 LSS Tactics Solved It)

Published:This major beverage manufacturer was spending millions of dollars per year to replace recyclable plastic shells to transport 2-liter bottles from the plant to their customers. Where did all the plastic shells go? Let’s find out. The process of retrieving delivered plastic shells from the customer should have been easy, but apparently it wasn’t. The […]

Read more »

Process Management

Published:Process management is a structured process for assuring that all your processes are aligned to ensure you can attain the organization’s strategic goals.

Read more »

Following the Road to Improvement

Published:As a recently promoted Vice President, Chuck needed to quickly understand what all his people were doing. Chuck, a longtime employee of a major utility company, had been recently promoted to Vice President to take over the leadership of a wide range of different functions than what he had been managing. As a result of […]

Read more »

Risk Based Maintenance (RBM)

Published:A method of prioritizing maintenance needs of various components or systems based on the severity of the risk of failure.

Read more »

Mean Time to Repair (MTTR)

Published:The average time to repair a machine back to acceptable operating conditions.

Read more »

Error Cause Removal

Published:Eliminating the cause of an error in order to keep the error from happening again.

Read more »

Jack in the Box

Published:Jack in the Box can be defined as a variable that appears randomly in response to factors that are not readily apparent.

Read more »

Frequently Committed Errors (FCE)

Published:Frequently committed errors (FCE) are anomalies in a particular process that have a negative impact on the outcome.

Read more »

Extract Load Transfer (ELT)

Published:ELT (Extract, Load, Transfer) is a data management method that transfers raw data from a source server to a target server and prepares the data for downstream use.

Read more »

Business Metric

Published:Business metrics are metrics that are quantifiable and utilized to assess the performance or status of a business function.

Read more »

Six Thinking Hats

Published:Have you ever been on an improvement team that just doesn’t work as well as you expected? Was it because people weren’t trying or was the mix of personalities and perspectives not conducive to working together for a solution? Let’s see how one company handled this problem. Using the Six Thinking Hats helped this company […]

Read more »

U Chart

Published:A U chart is one of four quality control charts that engineers use to track variation in a manufacturing process.

Read more »

Mean Time Between Failures (MTBF)

Published:Mean Time Between Failure is a basic metric that describes the frequency of problems in physical equipment or systems that disrupt production uptime.

Read more »

Box-Cox Transformation

Published:The Box-Cox transformation can be used for converting the data to a normal distribution, which then allows the process capability to be easily determined.

Read more »

Operation Cost Target (OCT)

Published:An operation cost target is the maximum expenditure allowed for all costs that are associated with a project, including overhead, materials, labor, outsourcing, and other costs.

Read more »

How Motorola’s Continuous Improvement Efforts Led to Record Growth and Profit

Updated:While Motorola had been an industry leader for decades, by the 1970s, many of its products were seen as potentially unreliable by consumers. The company addressed this issue by embarking aggressively on an innovative program of continuous improvement that has come to be known as Six Sigma. How Continuous Improvement Changed Consumer Perception Of Motorola […]

Read more »

Strategic Planning: Defining Vision, Goals, and Objectives for Success

Updated:Strategic planning is a disciplined effort to produce fundamental decisions and actions that shape and guide what an organization is, what it does, and why it does it, with a focus on the future.

Read more »

Capability Maturity Model (CMM)

Published:An established framework for the ongoing improvement of software development and implementation practices.

Read more »

Convert DPMO/Sigma to Cpk

Published:DPMO, Sigma Level and Cpk are three metrics you can use to measure how well your process is performing.

Read more »

Subject Matter

Published:Subject matter refers to all things related to your company’s products, services, or customers.

Read more »

Mura

Published:Mura is a Japanese word meaning unevenness, non-uniformity, and irregularity.

Read more »

FMEA

Published:FMEA stands for Failure Mode Effects Analysis and allows you to think through all of the possible ways something can go wrong, then find ways to mitigate those risks, so that your project is more likely to succeed.

Read more »

Alias

Published:An alias indicates that you’ve changed two or more things at the same time in the same way. Aliasing is a synonym for confounding.

Read more »

How Process Maturity Models Help Organizations Achieve Higher Levels of Performance

Updated:Process maturity is a concept used by the Lean Six Sigma (LSS) methodology to evaluate and optimize business processes.

Read more »

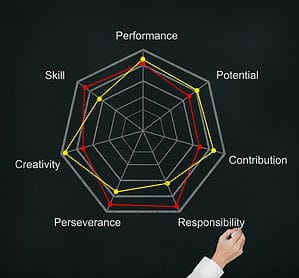

Radar Charts: The Visual Tool for Multi-Dimensional Data Comparison

Updated:A radar chart, also known as a spider chart, is a great tool to graphically compare multiple outcomes for specific characteristics and criteria.

Read more »

How to Use Entitlement to Drive Process Improvement

Updated:Entitlement is defined as the best performance you can reasonably achieve with the existing process.

Read more »

The Benefits of Using Flowcharts in Six Sigma Projects

Updated:A flowchart is a diagram of a process, using standard symbols to represent a variety of process activities over a specified timeline.

Read more »

Linearity vs. Repeatability: What’s the Difference?

Updated:What Is Linearity? Before we can understand linearity, we must understand another measurement error known as bias. Bias is a consistent mistake that occurs in measurement. For example, every measure taken with your scale comes out heavier than the actual weight. Linearity measures the consistency of a bias over the entire range of possible measurements. […]

Read more »

Common Cause vs. Special Cause Variation: What’s the Difference?

Updated:What is Common Cause Variation? Common cause variation is the kind of variation that is part of a stable process. These are variations that are natural to a system and are quantifiable and expected. Common cause variations are those that are predictable, ongoing, and consistent. Major changes would typically have to be made in order […]

Read more »

How to Incorporate SS Process Reports into Your Quality Processes

Updated:The Six Sigma process report is a Minitab tool that calculates process capability and provides visuals of process performance.

Read more »

How to Identify and Eliminate FISH Inventory in Your Business

Updated:First in Still Here (FISH) is a term that refers to very slow-moving inventory.

Read more »

Design Verification, Production and Process Validation (DVP&PV)

Published:The process where planning, testing, and reporting occur in the design or prototype stage in the development of a product.

Read more »

Tangible vs. Intangible Benefits: What’s the Difference?

Published:What Are Tangible Benefits? Tangible benefits are positive results that can be accurately measured and quantified with standard measurements. In business, the term describes any kind of outcome that is directly associated with financial gain or loss. You can always boil down tangible benefits to a monetary value relative to other types of investments or […]

Read more »

Null Hypothesis vs. Hypothesis

Published:Null Hypothesis vs. Hypothesis: What’s the Difference? What Is Null Hypothesis? A null hypothesis is a prediction that there is no statistical relationship between two variables or two sets of data. Essentially, a null hypothesis makes the assumption that any measured differences are the result of randomness and that the two possibilities are the same […]

Read more »

What is Return on Net Assets? A Complete Guide

Updated:RONA is one bottom-line measurement showing performance relative to strategic goals and objectives.

Read more »

Confirmation is Key to Reducing Risk and Increasing Accuracy

Updated:Confirmation is a way to confirm that a process is working as expected. It can be used to validate or invalidate a hypothesis, test a process or product and test the process of testing.

Read more »

Achieving Organizational Excellence through GOAL Deployment

Updated:Using GOAL Deployment in support of their Strategic Plan, this company was able to align goals and objectives and achieve impressive organizational improvements The Company historically used yearly Strategic Planning to lay out its macro goals and initiatives. This was done by each functional area of the company submitting what they believed they wanted to […]

Read more »