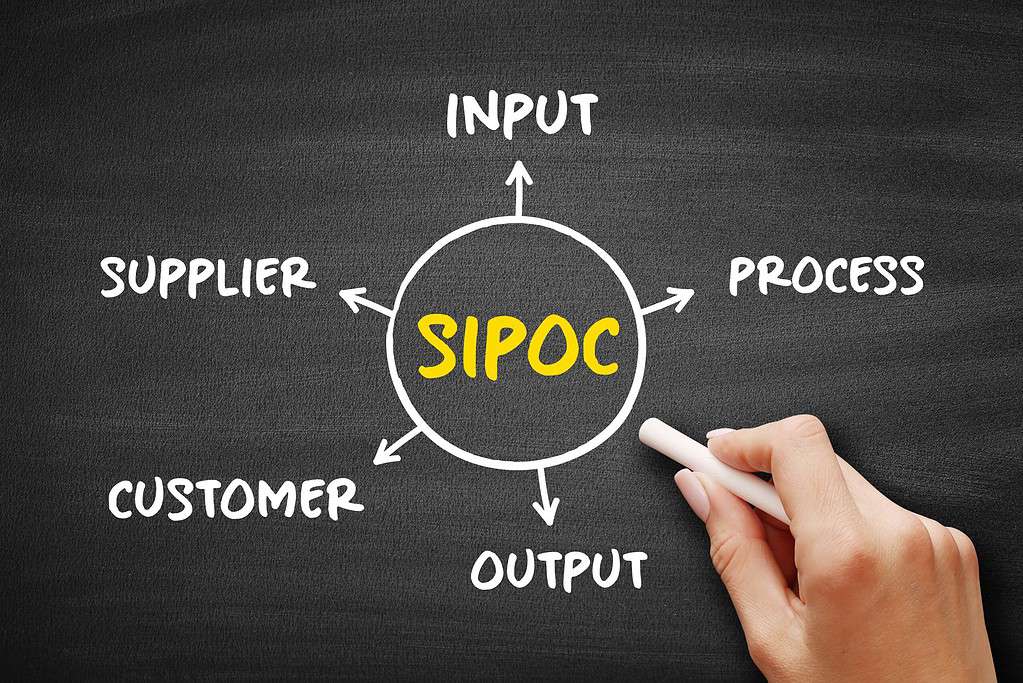

Tag: SIPOC

Common Mistakes When Using SIPOC

Published:What are the most common mistakes when using SIPOC? The SIPOC Diagram is one of the most useful tools in your arsenal when it comes to process analysis. It readily allows you and your team to grasp the various elements of a process before diving fully into detail on how everything fits together. […]

Read more »

Get Your Team Up to Speed with the SIPOC Diagram

Published:There are a few different ways you can improve a process in your business. Before you get to work with implementing these changes, it does help to visualize the entire thing. A SIPOC diagram is a highly useful tool for mapping out the steps of a process. Processes and projects are complex, but […]

Read more »

Case Study: Edward Jones Adds Robotic Process Automation with Lean Six Sigma

Published:In only three years, Edward Jones has realized more than a million dollars in cost avoidance through the use of bots combined with LSS.

Read more »

SIPOC: Beyond Process Mapping

Published:The Six Sigma tool SIPOC (supplier, input, process, output, customer) is used to map processes at a high level. SIPOC diagrams are typically included as a slide in project presentations – often as a required element of a presentation template – accompanied by a perfunctory description. Presenters may not know what do with the SIPOC […]

Read more »

Mastering the Use of SIPOC

Published:One of the most popular search terms on iSixSigma.com is SIPOC (suppliers, inputs, process, output and customers), a process mapping tool. The reverse of SIPOC, COPIS (customer, output, process, input, supplier) is also a frequently searched tool. The best SIPOC/COPIS references on iSixSigma can be found at the following links: Better Involvement/Requirements with LURE and […]

Read more »

Using the DMAIC Model to Achieve Buy-in

Published:When project managers begin studying Lean Six Sigma, the first question asked is often, “How will I get buy-in?” Although the core concepts and methodologies may make sense to project managers, the question of buy-in sometimes overshadows this powerful methodology for process improvement. There are many root causes for why people are reluctant to lend […]

Read more »

Harvesting Value in Transactional Processes with Lean Six Sigma

Published:While transactional processes might require a different approach, the Lean Six Sigma tools you use are the same. Follow this sequence of five tools to begin fixing your invisible problems before they reach your customers.

Read more »

Preventing Conflicts Through Stakeholder Management

Published:A stakeholder of a Six Sigma project is anyone associated with the project either directly or indirectly. Examples of stakeholders are supervisors providing resources, team members, department heads and employees involved in the process. An up-front analysis of who the stakeholders are and how and when to involve them in the project can prevent potential […]

Read more »

Better Involvement/Requirements with LURE and COPIS

Published:Implementing technology requires stakeholder involvement and good requirement development. When there is a misalignment in those areas businesses and their customers both suffer. LURE and COPIS can clarify perspectives and help avoid misalignment.

Read more »

Six Sigma Strategy: Understanding the Customer Process

Published:Many companies which choose not to utilize Lean and Six Sigma as key components of how they implement change in their organization say it is because the methodologies are too complicated for their business environment. They claim that they do not have the time to build an infrastructure, train Black Belts and Green Belts and […]

Read more »

Blending Process Analytical Technology and Six Sigma

Published:By Terra Vanzant-Stern Manufacturers face numerous challenges within their markets as the number of competitors grows and increasing material costs impact margins. Business methodologies such as Lean Six Sigma working in tandem with industry-specific approaches can increase the opportunity for success. An example of that is in the pharmaceutical industry, where an approach called process […]

Read more »

P&R IM Improves Management of Health Treatment Records

Published:Personnel and Readiness Information Management (P&R IM), Office of the Under Secretary of Defense (Personnel and Readiness), led an in-depth analysis of the Health Treatment Record (HTR) life cycle management process. The HTR is the chronological documentation of medical, dental and mental health care received by a service member during the course of his or […]

Read more »

Hocus POCIS: The Magic of the SIPOC Diagram

Published:The SIPOC (suppliers, inputs, process, outputs, customers) process map is one of the most valuable tools in a Six Sigma professional’s toolbox. It typically can be completed with the project team in less than an hour, and has a strong tie to the project charter. It also makes previously unknown customers suddenly appear out of […]

Read more »

Tools That Complement SIPOC and Help Uncover Details

Published:A SIPOC (suppliers, inputs, process, outputs, customers) diagram is a standard part of most Six Sigma projects for good reason: It helps a team to pose and answer important questions about customers, suppliers, requirements and dependencies. In many cases a SIPOC table and a simple process map can go a long way in discovering the […]

Read more »

Identifying High-Level Requirements Using SIPOC Diagram

Published:Often times it almost seems as if the people who run a business and the people developing and implementing the information technology (IT) systems for the business do not speak the same language. So it was with a project team that had developed a high-level, future-state process map for a renewal process in the insurance […]

Read more »

Improving Lean Six Sigma Process with Lean Six Sigma

Published:Lean Six Sigma is a process improvement program, a management engineer would say, that is built upon basic industrial engineering techniques. The program combines two ideas – Lean and Six Sigma. Lean is a collection of techniques for decreasing the time to provide products or services by eliminating process and time waste. Six Sigma is a […]

Read more »

Combining SIPOC with the Cause-and-Effect Diagram

Published:Six Sigma practitioners strive to find the root causes of defects fast and accurately. One of the tools that provides a good initial view of the process Six Sigma is being used to optimize is SIPOC (supplier, input, process, output, customer). This tool is especially helpful when the improvement project is aimed at a process […]

Read more »

SIPOC Leads to Process Mapping and Project Selection

Published:Companies new to Six Sigma need an agreed-upon, easily communicated picture of current processes (“as is” state). Building a SIPOC diagram is a good starting point.

Read more »

Attention Six Sigma, You’re Wanted in Surgery

Published:With the demand for surgical services growing, especially with ambulatory and cosmetic procedures, hospitals continue learning that Six Sigma is a useful tool.

Read more »

A Six Sigma Case Study – Tutorial for IT Call Center – Part 3 of 6

Published:This combination “case study and tutorial” tracks the inception of a Six Sigma DMAIC project by an IT support business. The project is aimed at helping the company become more competitive and profitable. Each part follows the project team as it works through another stage of the DMAIC methodology. Click to read the rest of […]

Read more »

Important to Understand the Process Before Improving It

Published:To create sustained continuous improvements in organizational processes, an organization must first understand its processes. In a services environment, this can be difficult. A service by its very nature requires human interaction – people serving people. This means that a single organizational process may be perceived as diversely as the people performing it. And with merger […]

Read more »